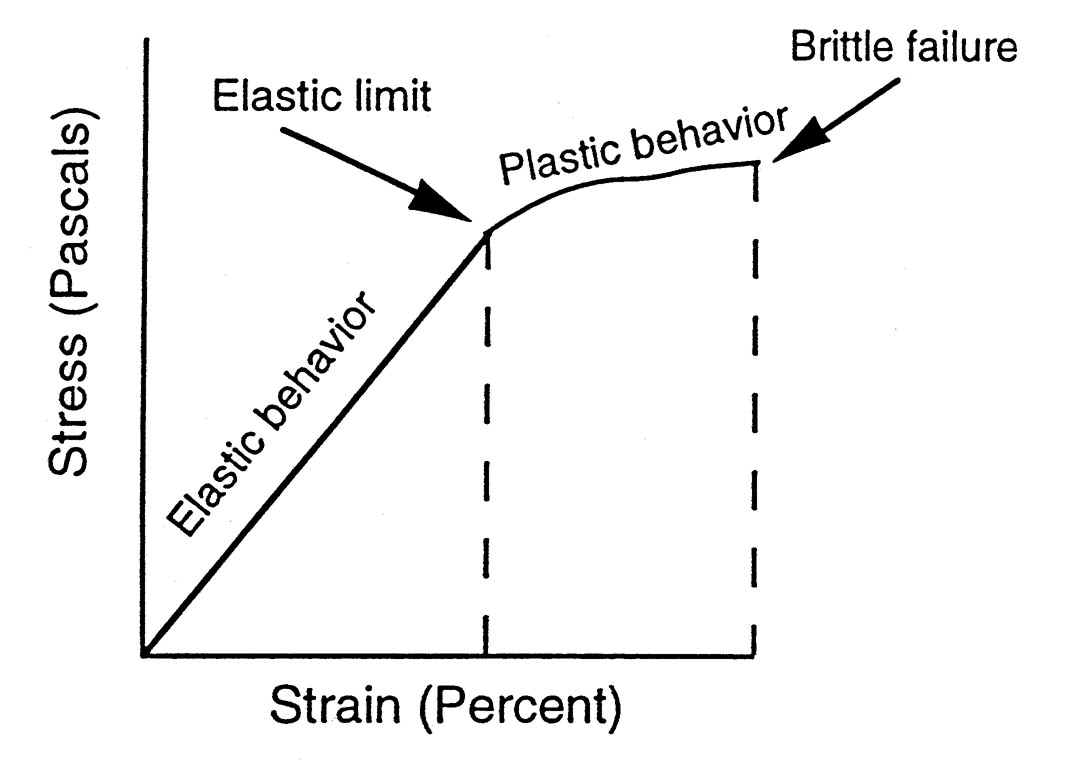

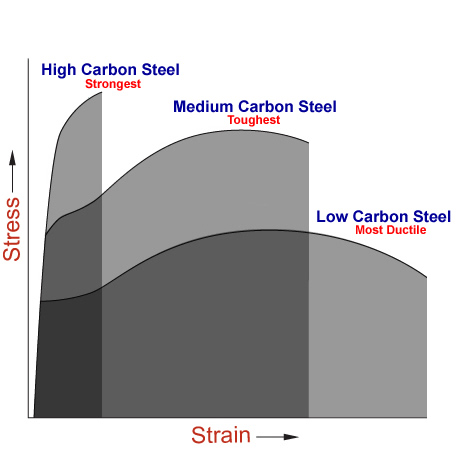

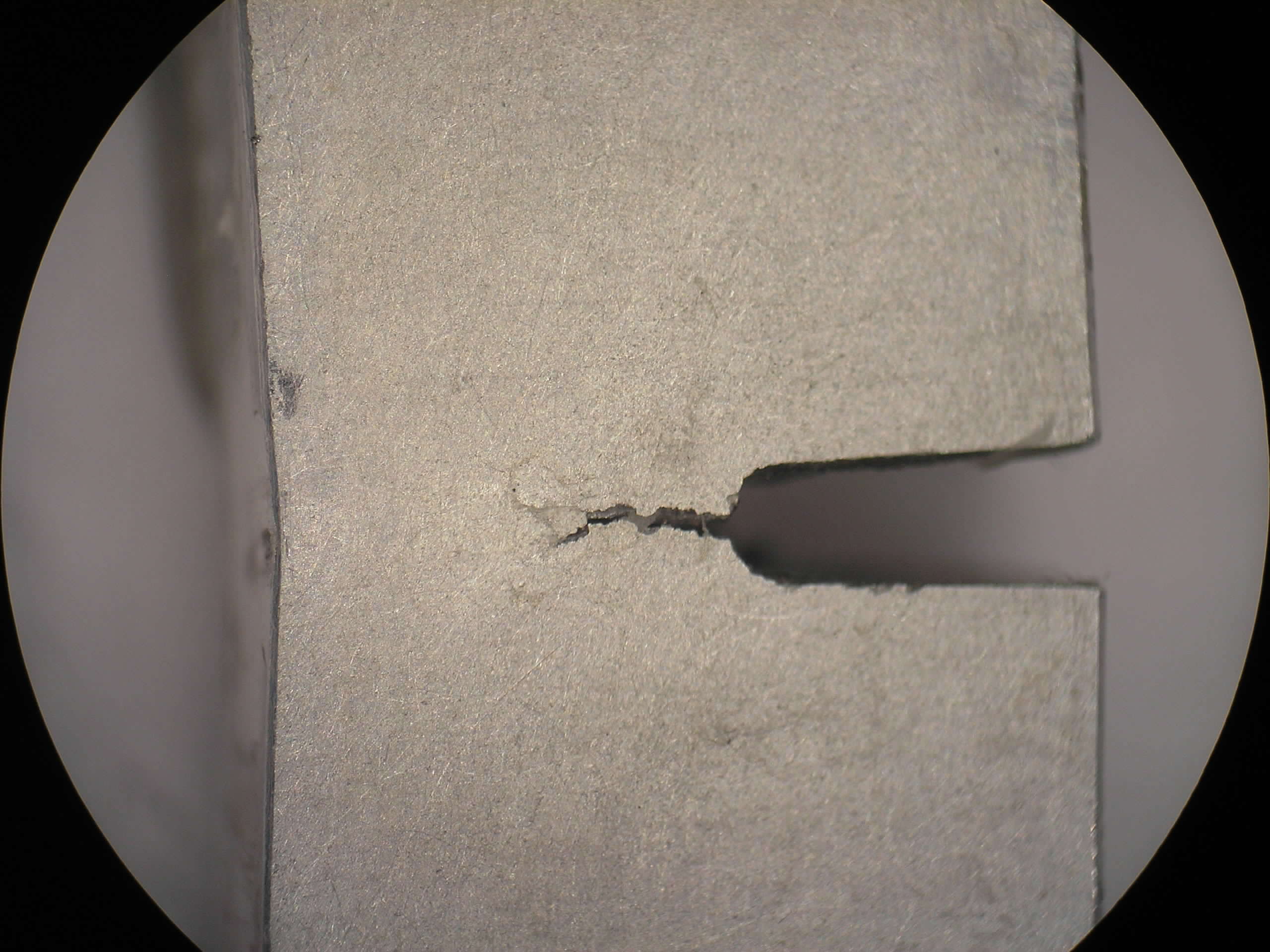

A is generally said to be brittle if it cannot be deformed to any appreciable degree prior to fracture. This behaviour does not imply that the ultimate tensile strength measured on a smooth specimen during a tensile test is low. On the contrary, the opposite phenomenon is usually observed. Hardening treatments which aim to increase strength are usually accompanied by a dramatic degradation of ductility and tend to enhance brittleness.

Brittle Failure Curve

Brittle Failure Curve

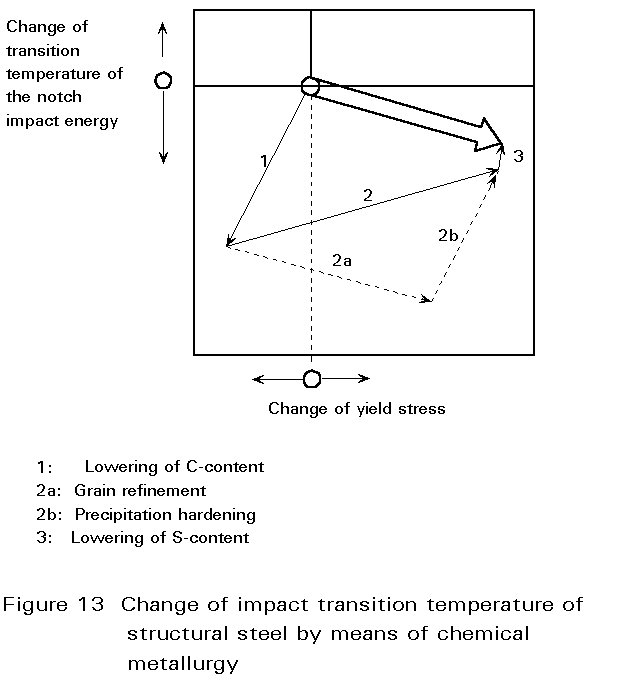

Brittleness is neither an absolute nor a simple concept. As a rule, the susceptibility to brittle behaviour in a given material is increased by:

- the lower the temperature to which it is exposed.

- the more rapid the loading to which it is submitted.

- the more disturbed the stress distribution it experiences.

Brittleness is influenced by ductility, i.e. the capacity of a material to strain plastically, and by strain-hardenability, i.e. the property of developing a higher strength while undergoing plastic deformation.

You might also like

| Fracture Toughness Fracture mechanics provides a quantitative... | Optimal Combination of STRENGTH and TOUGHNESS Preceding sections have described the influence... | Toughness Metals often show quite acceptable properties... | Fracture Mechanics Concepts The basis of a fracture mechanics safety... |

Alloy Suppliers

Alloy Suppliers

Aluminum

Aluminum

Aluminum Extrusions

Aluminum Extrusions

Copper-Brass-Bronze

Copper-Brass-Bronze

Nickel

Nickel

Magnets

Magnets

Stainless Steel

Stainless Steel

Stainless Steel Tubing

Stainless Steel Tubing

Steel Service Centers

Steel Service Centers

Titanium

Titanium

Tungsten

Tungsten

Wire Rope

Wire Rope