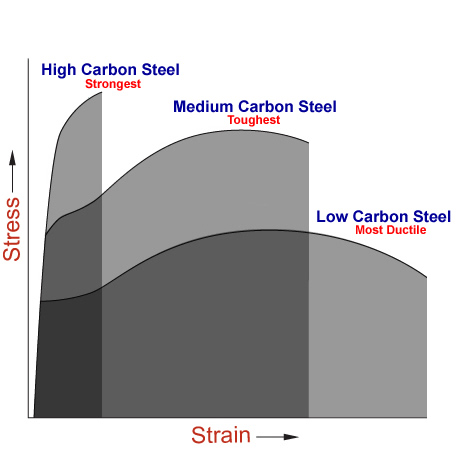

According to European standard EN 10 020, steel is a material which contains by weight more iron than any other single element, having a carbon content generally less than 2% and containing other elements (Figure 1). A limited number of chromium steels may contain more than 2% of carbon, but 2% is the usual dividing line between steel and cast iron.

Steel Wire

Steel Wire

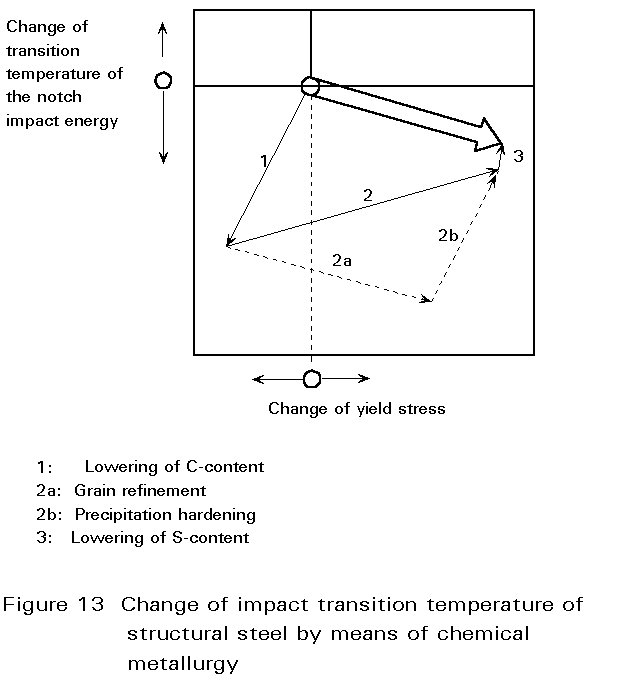

Due to its high strength, its good machineability and its high economic efficiency, steel is one of the most important construction materials. By changes in the chemical composition and in the production conditions, it is possible to vary steel properties over a wide range and the steel manufacturer is able to adapt the properties to the specific requirements of users.

You might also like

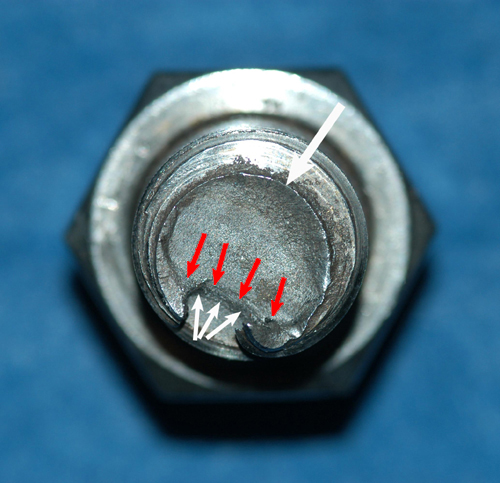

| Optimal Combination of STRENGTH and TOUGHNESS Preceding sections have described the influence... | Failure analysis Failure analysis is the process of... | Austempered Ductile Iron (ADI) Austempered Ductile Iron (ADI) is... | Fracture Mechanics Concepts The basis of a fracture mechanics safety... |

Alloy Suppliers

Alloy Suppliers

Aluminum

Aluminum

Aluminum Extrusions

Aluminum Extrusions

Copper-Brass-Bronze

Copper-Brass-Bronze

Nickel

Nickel

Magnets

Magnets

Stainless Steel

Stainless Steel

Stainless Steel Tubing

Stainless Steel Tubing

Steel Service Centers

Steel Service Centers

Titanium

Titanium

Tungsten

Tungsten

Wire Rope

Wire Rope