Formation of martensite and bainite

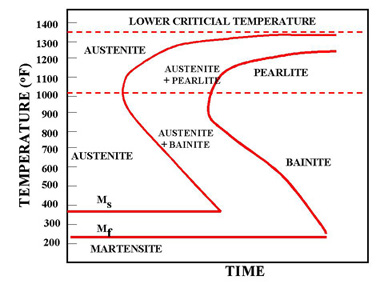

Normalising causes steels to undercool below the requirements of the phase diagram before the austenite transforms into fine ferrite and pearlite. Still further increases in cooling rate give further undercooling and still finer microstructures. Very rapid cooling by quenching into cold water, causes the formation of ferrite and pearlite to be suspended.

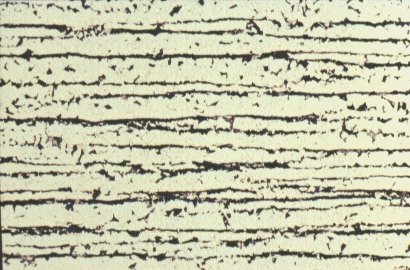

Longitudinal section of hot rolled structural steel showing dark bands of pearlite in a ferrite matrix.(x 200)

Longitudinal section of hot rolled structural steel showing dark bands of pearlite in a ferrite matrix.(x 200)

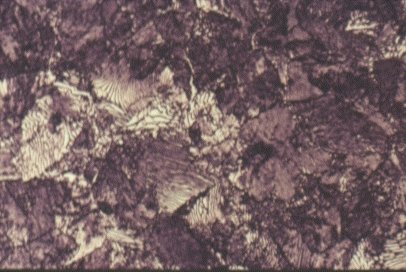

The internal diffusion-controlled rearrangement of atoms needed to form those products cannot occur sufficiently rapidly. Instead, new products are formed by microstructural shear transformations at lower temperatures. Very fast cooling gives martensite: its microstructure is shown above. When martensite forms, there is no time for the formation of cementite and the austenite transforms to a highly distorted form of ferrite which is super saturated with dissolved carbon.

The combination of the lattice distortion and the severe work hardening resulting from the shear deformation processes necessary to achieve the transformation cause martensite to be extremely strong but very brittle. Less rapid cooling can give a product called bainite. This is similar to tempered martensite where much of the carbon has come out of solution and formed fine needles of cementite which reinforce the ferrite.

You might also like

| Bainite Bainite is an acicular microstructure... | Cooling Rate Cooling Rate During Austenite to Ferrite... | Fe-Fe3C T-T-T Diagram Fe-Fe3C T-T-T Diagram, Adapted from... | Time-Temperature-Transformation (TTT ) Diagram T (Time) T(Temperature) T(Transformation)... |

Alloy Suppliers

Alloy Suppliers

Aluminum

Aluminum

Aluminum Extrusions

Aluminum Extrusions

Copper-Brass-Bronze

Copper-Brass-Bronze

Nickel

Nickel

Magnets

Magnets

Stainless Steel

Stainless Steel

Stainless Steel Tubing

Stainless Steel Tubing

Steel Service Centers

Steel Service Centers

Titanium

Titanium

Tungsten

Tungsten

Wire Rope

Wire Rope