Annealing of Steel Heat Treatment

Annealing is a heat treatment that alters the microstructure of a material causing changes in properties such as strength and hardness and ductility. Annealed metals are relatively soft and can be cut and shaped more easily. They bend easily when pressure is applied. As a rule they are heated and allowed to cool slowly. Annealing is a heat process whereby a metal is heated to a specific temperature and then allowed to cool slowly. This softens the metal which means it can be cut and shaped more easily. Mild steel, is heated to a red heat and allowed to cool slowly. However, metals such as aluminium will melt if heated for too long.

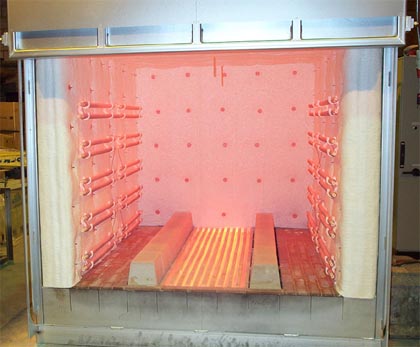

Annealing Heat Treatment of Cylinders

Annealing Heat Treatment of Cylinders

Process Annealing is used to treat work-hardened parts made out of low-Carbon steels (< 0.25% Carbon). This allows the parts to be soft enough to undergo further cold working without fracturing. Process annealing is done by raising the temperature to just below the Ferrite-Austenite region, line A1 on the diagram.

You might also like

| Heat Treatment Furnaces Heat Treatment Furnaces of Steel Heat treating... | Heat Treatment of Steel - the Steel Hardening Methods Heat Treatment of Metal - the Steel Hardening... | What is Malleable Cast Iron ? Malleable Cast Iron - a Definition Malleable... | Types of Heat Treatments Heat Treatment of Steel Heat Treatment is... |

Alloy Suppliers

Alloy Suppliers

Aluminum

Aluminum

Aluminum Extrusions

Aluminum Extrusions

Copper-Brass-Bronze

Copper-Brass-Bronze

Nickel

Nickel

Magnets

Magnets

Stainless Steel

Stainless Steel

Stainless Steel Tubing

Stainless Steel Tubing

Steel Service Centers

Steel Service Centers

Titanium

Titanium

Tungsten

Tungsten

Wire Rope

Wire Rope