Gold Corrosion - How it works?

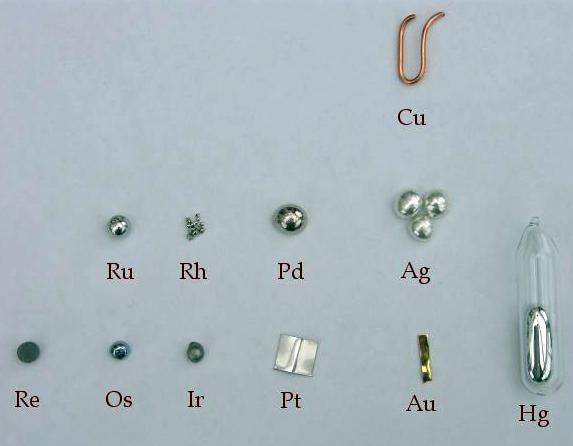

Gold is the most non-reactive of all metals and is benign in all natural and industrial environments. Gold never reacts with oxygen (one of the most active elements), which means it will not rust or tarnish. Gold tarnish is very thin and shows up as a darkening of reflecting surfaces.

Gold is the most non-reactive of all metals and is benign in all natural and industrial environments. Gold never reacts with oxygen (one of the most active elements), which means it will not rust or tarnish. Gold tarnish is very thin and shows up as a darkening of reflecting surfaces.

Gold is among the most electrically conductive of all metals. Since electricity is basically the flow of charged particles in a current, metals that are conductive allow this current to flow unimpeded. Gold is able to convey even a tiny electrical current in temperatures varying from -55° to +200° centigrade. Gold is the most non-reactive of all metals and is benign in all natural and industrial environments. Gold never reacts with oxygen (one of the most active elements), which means it will not rust or tarnish. Gold tarnish is very thin and shows up as a darkening of reflecting surfaces.

“Purple plague” is a brittle gold aluminum compound formed when bonding gold to aluminum. The growth of such a compound can cause failure in microelectronic interconnection bonds.

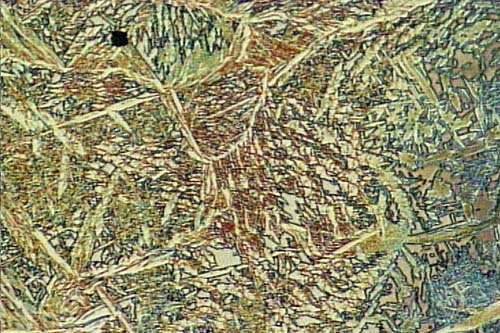

Gold Tarnishing

Possible causes include:

- Perspiration (everyone’s body chemistry is different, hence this is why some are more susceptible than others); for women, the time of the month can influence their body chemistry.

- Perfume, hair or deodorant sprays,

- Tarnishing during storage (storage boxes may contain organic sulfur compounds),

- Leaching of acid/ cleaning solutions from surface microporosity from cast jewelry; this causes corrosion locally (such porosity may even trap perspiration during wear, causing local corrosion)

- Preparation of vegetables such as onions and spices (many foodstuffs contain sulfur compounds and others are also acidic).

Another possible mechanism may be surface micro-porosity on the surface of investment (lost wax) cast items. This porosity may trap acids and other cleaning solutions, sprays, or perspiration and cause a local corrosion which ‘creeps’ over the surface of the item.

Alloy Suppliers

Alloy Suppliers  Aluminum

Aluminum  Aluminum Extrusions

Aluminum Extrusions  Copper-Brass-Bronze

Copper-Brass-Bronze  Nickel

Nickel  Magnets

Magnets  Stainless Steel

Stainless Steel  Stainless Steel Tubing

Stainless Steel Tubing  Steel Service Centers

Steel Service Centers  Titanium

Titanium  Tungsten

Tungsten  Wire Rope

Wire Rope