What is Micro Welding ?

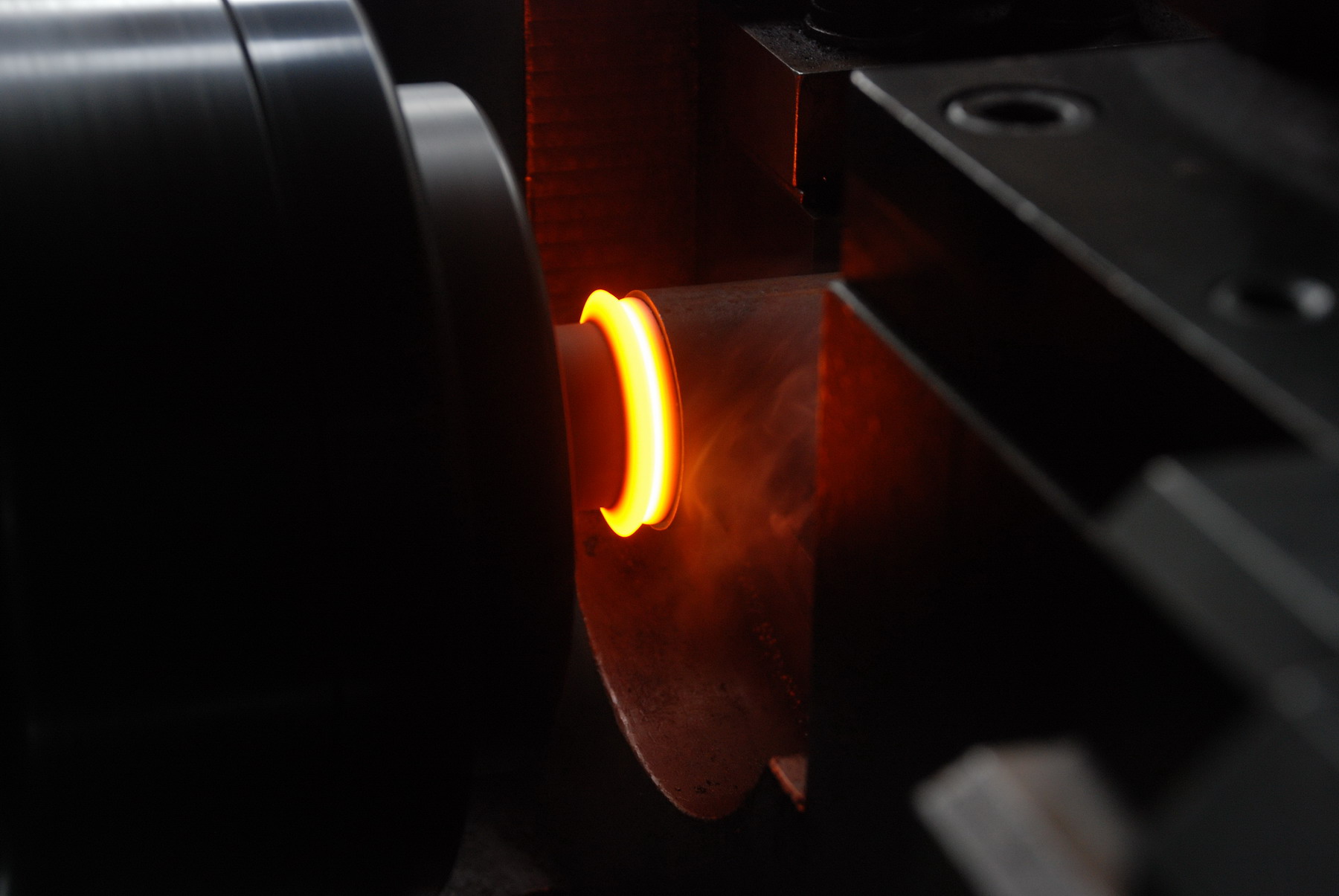

Micro-welding is a set of different technologies and equipment that have in common the unique specialty of being able to perform welding on thin or delicate materials by depositing welded metal in very small lumps, using minimal, consistent heat energy tightly controlled. The welding processes are designed to maintain tight operational tolerances and not to interfere with product function and quality.

Micro Welding

Micro Welding

Miniature devices and applications where components must be welded, require that the equipment used for Micro welding be capable of locating the hardware itself with the required precision and of depositing the due amount of energy for welding in the exact spot where it is needed, with minimum interference with the surroundings.

Although Micro-welding, also called precision welding, is not a standard term identifying a specific process, and recognized as such by the AWS Terms and Definitions Committee, it is a loose description of any process applicable to thin or tiny joints for the purpose of establishing a permanent connection.

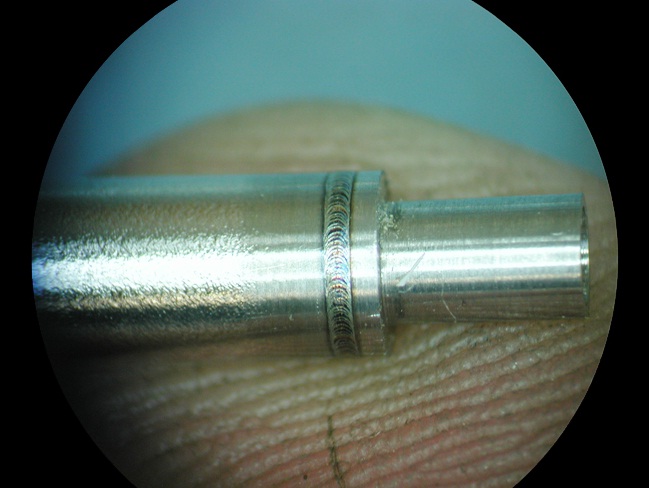

Also on the size there is not yet universally accepted consensus. A common definition considers micro welds all those having fusion zone dimensions less than 100 µm (1 micron = 0.001 mm). Another definition would accept welds less than 0.5 mm wide as micro welds. Practically any welding process suitable to be miniaturized in order to accomplish required diminutive welding could be included in the Micro-welding term.

The following processes have been applied with success to Micro-welding : resistance, flash, arc (tig, mig and plasma) and laser. Also electron beam welding could be considered for miniature welding. Applications include tiny medical implants, lamps and lighting assemblies, jewelry, dental appliances, aerospace items, hermetic sealing, batteries, thermocouples, wires, TV tube parts, sensing devices, electronic instrumentation, molds and tool build up and many other types of miniature work.

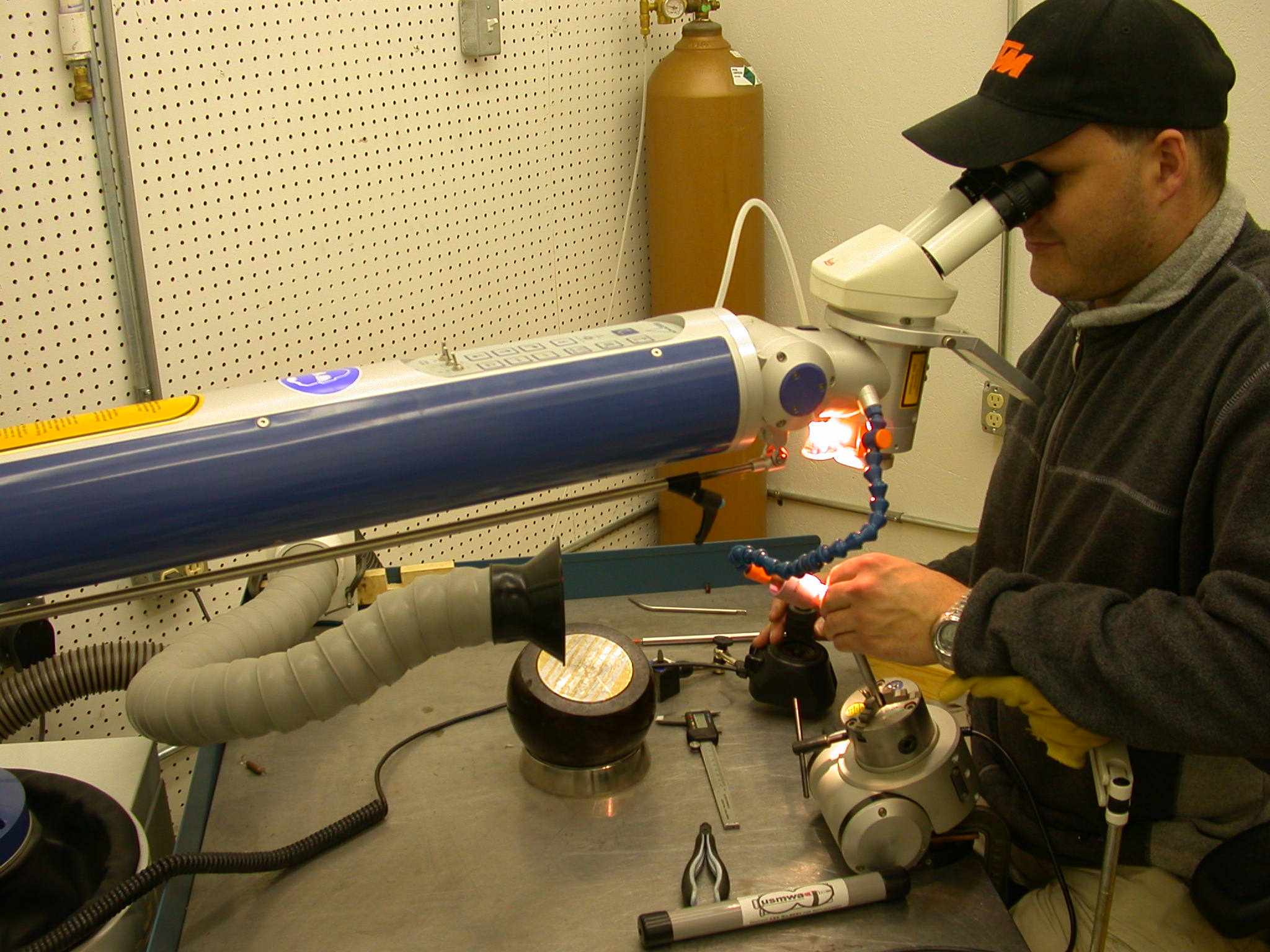

Many experienced welding shops are ready to take in custom specified work of this kind, from those willing to outsource special production technologies that cannot be done in house. Most of the Micro-welding operations in this category are carried out under a microscope to place exactly the hardware elements and filler (if present) and to control performance. Other applications, fully automated for mass production, do not require any particular skill on the part of operators.

You might also like

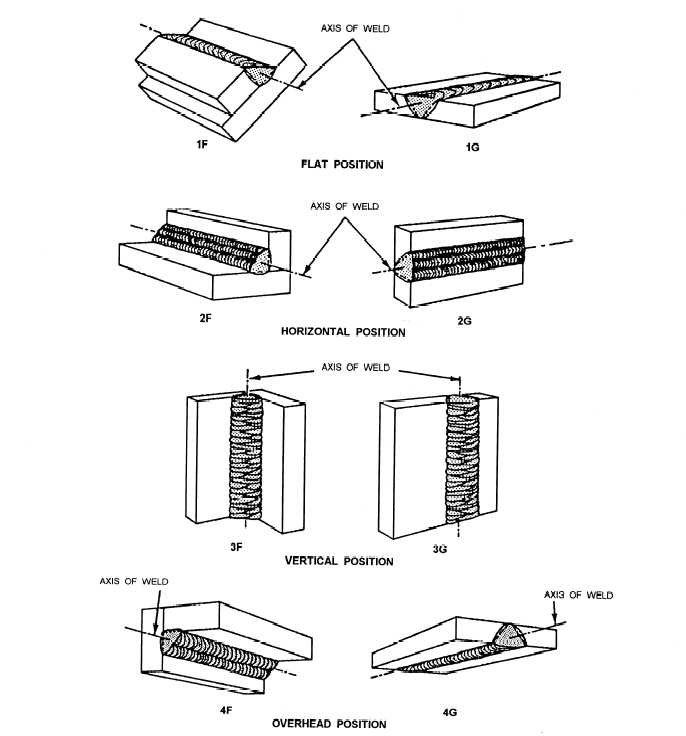

| How does Friction Welding Work ? What is Friction Welding ? Friction welding... | Welding Pictures Welding is a fabrication or sculptural process that... | Welding Procedure What Are Welding Procedures ? A Welding... | Welding Positions What`s Kind of Welding Positions ? Welding... |

Alloy Suppliers

Alloy Suppliers

Aluminum

Aluminum

Aluminum Extrusions

Aluminum Extrusions

Copper-Brass-Bronze

Copper-Brass-Bronze

Nickel

Nickel

Magnets

Magnets

Stainless Steel

Stainless Steel

Stainless Steel Tubing

Stainless Steel Tubing

Steel Service Centers

Steel Service Centers

Titanium

Titanium

Tungsten

Tungsten

Wire Rope

Wire Rope