What is Thermit Welding ?

Thermit Welding is a welding process utilizing heat generated by exothermic chemical reaction between the components of the thermit (a mixture of a metal oxide and aluminum powder). The molten metal, produced by the reaction, acts as a filler material joining the work pieces after Solidification.

Thermit Welding Process

The process employs an exothermic reaction of a copper thermite composition to heat the copper, and requires no external source of heat or current. The chemical reaction that produces the heat is an aluminothermic reaction between aluminium powder and a mixture of copper oxides (copper(II) oxide and copper(I) oxide), with chemical formula :

3CuO + 2Al — 3Cu + Al2O3 + Heat

Thermite is a pyrotechnic composition of a metal powder and a metal oxide that produces an exothermic oxidation-reduction reaction known as a thermite reaction. If aluminium is the reducing agent it is called an aluminothermic reaction.

Most varieties are not explosive, but can create short bursts of extremely high temperatures focused on a very small area for a short period of time. The thermite is simply a mixture of metal, often called the “fuel” and an oxidizer. Its form of action is very similar to other fuel-oxidizer mixtures like black powder.

This chemical reaction reaches a temperature of 1,400 °C (1,670 K). The reactants are usually supplied in the form of powders, with the reaction triggered using a spark from a flint lighter. The activation energy for this reaction is very high however, and initiation requires either the use of a “booster” material such as powdered magnesium metal or a very hot flame source. The aluminium oxide slag that it produces is discarded.

The process employs a semi-permanent graphite crucible mould, in which the molten copper, produced by the reaction, flows through the mould and over and around the conductors to be welded, forming an electrically conductive weld between them. When the copper cools, the mould is either broken off or left in place.

Thermit material is a mechanical mixture of metallic aluminum and processed iron oxide.Molten steel is produced by the reaction in a magnesite-lined crucible. At the bottom of the crucible, a magnesite stone is burned, into which a magnesite stone thimble is fitted.This thimble provides a passage through which the molten steel is discharged into the mold. The hole through the thimble is plugged with a tapping pin, which is covered with a fire-resistant washer and refractory sand.

The crucible is charged by placing the correct quantity of thoroughly mixed material in it.In preparing the joint for welding, the parts to be welded must be cleaned, alined, and held firmly in place.If necessary, metal is removed from the joint to permit a free flow of the metal into the joint. A wax pattern is then made around the joint in the size and shape of the intended weld. A mold made of refractory sand is built around the wax pattern and joint to hold the molten metal after it is poured.

The weld formed has higher mechanical strength than other forms of weld, and excellent corrosion resistance. It is also highly stable when subject to repeated short-circuit pulses, and does not suffer from increased electrical resistance over the lifetime of the installation. However, the process is costly relative to other welding processes, requires a supply of replaceable moulds, suffers from a lack of repeatability, and can be impeded by wet conditions or bad weather (when performed outdoors).

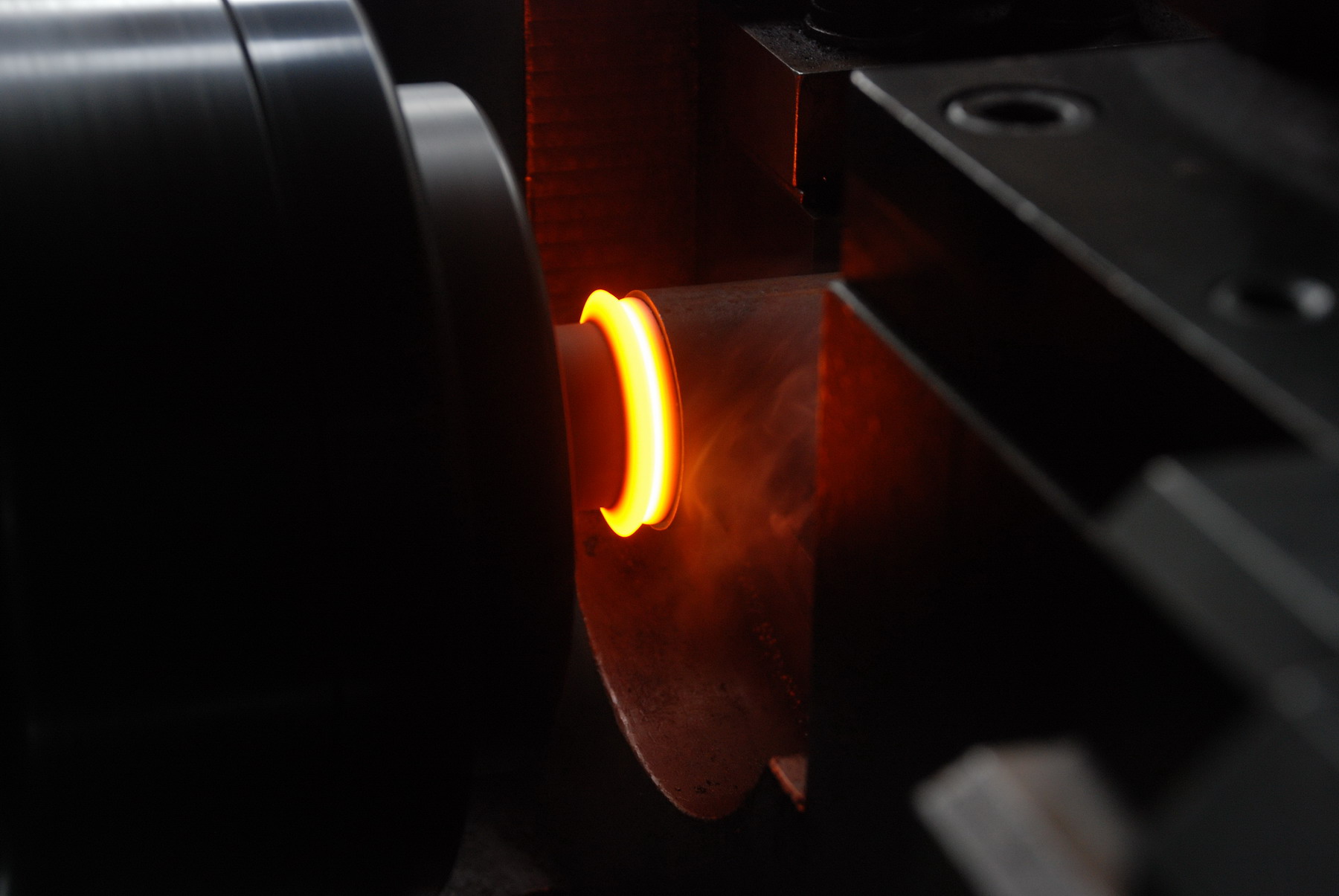

Thermite welding is widely used to weld railway rails. One of the first railroads to evaluate the use Thermite Welding was the Delaware Hudson in 1935 The weld quality of chemically pure thermite is low due to the low heat penetration into the joining metals and the very low carbon and alloy content in the nearly pure molten iron. To obtain sound railroad welds, the ends of the rails being thermite welded are preheated with a torch to an orange heat, to ensure the molten steel is not chilled during the pour. Because the thermite reaction yields relatively pure iron, not the much stronger steel, some small pellets or rods of high-carbon alloying metal are included in the thermite mix; these alloying materials melt from the heat of the thermite reaction and mix into the weld metal. The alloying beads composition will vary, according to the rail alloy being welded.

You might also like

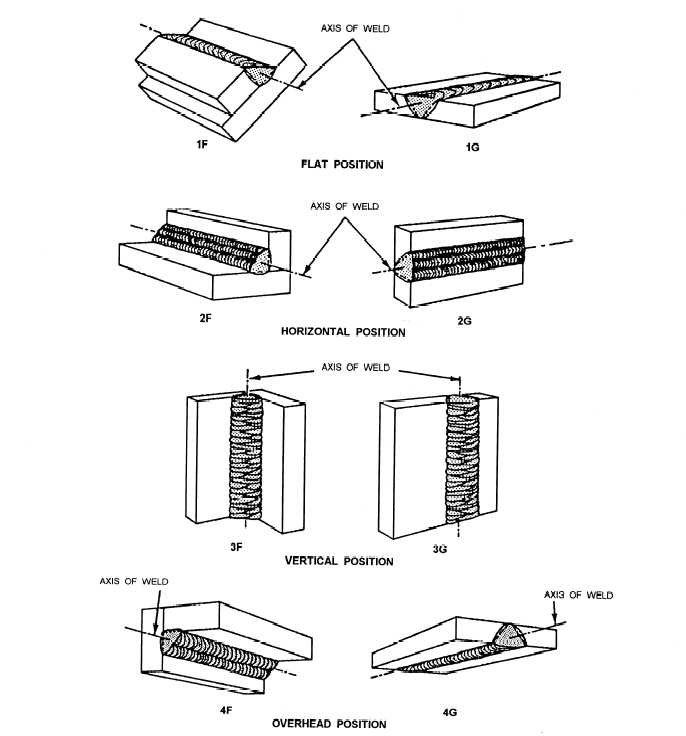

| Welding Pictures Welding is a fabrication or sculptural process that... | Welding Procedure What Are Welding Procedures ? A Welding... | Welding Positions What`s Kind of Welding Positions ? Welding... | How does Friction Welding Work ? What is Friction Welding ? Friction welding... |

Alloy Suppliers

Alloy Suppliers

Aluminum

Aluminum

Aluminum Extrusions

Aluminum Extrusions

Copper-Brass-Bronze

Copper-Brass-Bronze

Nickel

Nickel

Magnets

Magnets

Stainless Steel

Stainless Steel

Stainless Steel Tubing

Stainless Steel Tubing

Steel Service Centers

Steel Service Centers

Titanium

Titanium

Tungsten

Tungsten

Wire Rope

Wire Rope