What`s Kind of Welding Positions ?

Welding position gives an idea of the location of the workpiece which is to be welded. Location of a workpiece is generally decided with respect to weld slope and weld rotation which are defined below.

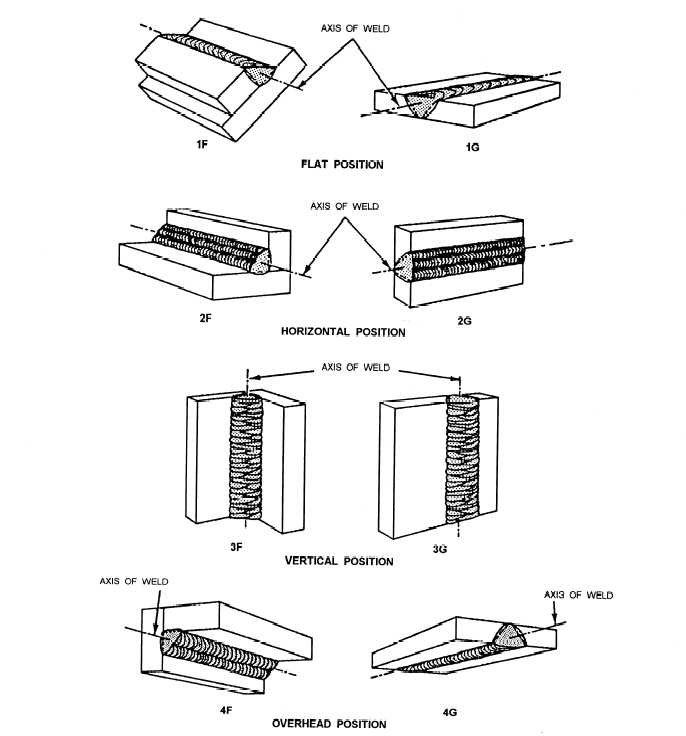

Welding Positions

Welding Positions

Slope

It is the angle between weld root line (W.R.L.) and a horizontal reference plane (H.R.P.)

Rotation

It is the angle between the line bisecting the angle of weld cross-section (B.L.) and upper portion of a vertical reference plane (V.R.P.) passing through the weld root line.

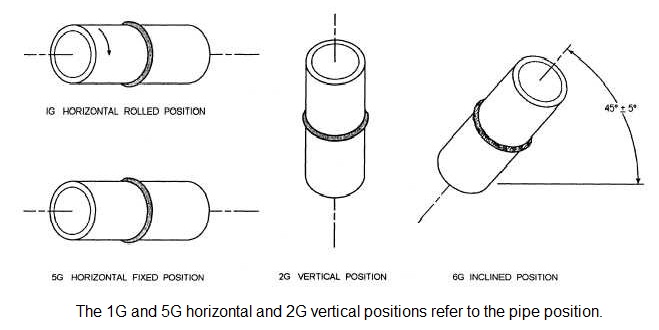

According to American standards there are basically four welding positions namely flat, horizontal, vertical and overhead; whereas British and Indian standards add one more, namely inclined position. Any of these five positions is obtained by a suitable combination of slope and rotation; for example.

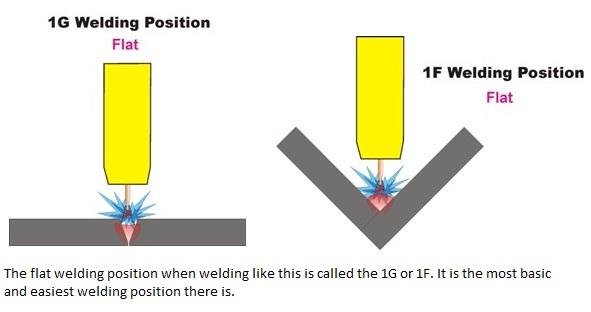

(1) Flat (down hand) position. In this position, the face of the weld is horizontal, welding is carried out from above, electrode pointing. downward and weld bead is horizontal. In a flat position both slope and rotation are limited within 10 degrees.

(2) Horizontal position. The plane of the workpiece is vertical, and the deposited weld bead is horizontal. In this position, slope does not exceed 10 degrees, but rotation can vary from 10-90 degrees.

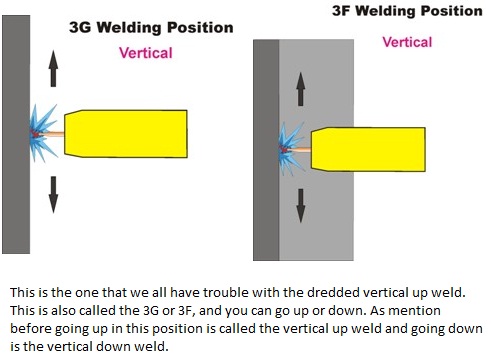

(3) Vertical position. The plane of the workpiece is vertical and the deposited weld bead is also vertical. In vertical position slope remains between 45 and 90 degrees and rotation may have any value from 0 to 180 degrees.

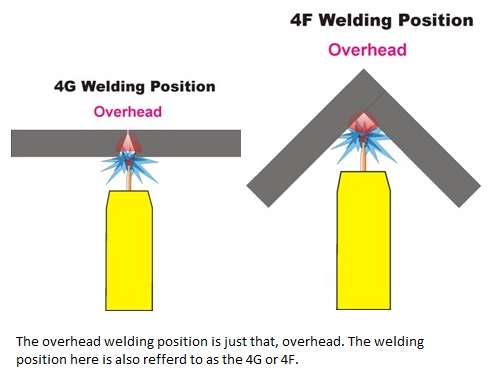

(4) Overhead position. The plane of the workpiece is horizontal; welding is carried out from the underside, electrode pointing upward. In this position slope and rotation can vary from 0 to 45 and 90 to 180 degrees respectively.

(5) Inclined position. In this case slope and rotation can vary from 10 to 45 and 0 to 90 degrees respectively. The workpiece is in an inclined plane.

The simplest, best, natural and the most convenient position for welding is flat (down hand). Excellent welded joints at a fast speed and with minimum fatigue to the welders are obtained. If the structure does not permit welding in flat position, and if possible, the same may be rotated, using rotators, fixtures or positioners in order to carry out welding in flat position.

FLAT WELDING POSITIONS

VERTICAL WELDING POSITIONS

OVERHEAD WELDING POSITIONS

Basically there are three inclinations involved :

- Flat, which includes from 0 to 15 degrees inclination

- 15 - 80 degrees inclination

- Vertical, 80 - 90 degrees

For each of these inclinations the weld can be rotated from the flat position to Horizontal to overhead.

For each of these inclinations the weld can be rotated from the flat position to Horizontal to overhead.

Rotation

It is the angle between the line bisecting the angle of weld cross-section (B.L.) and upper portion of a vertical reference plane (V.R.P.) passing through the weld root line.

Alloy Suppliers

Alloy Suppliers  Aluminum

Aluminum  Aluminum Extrusions

Aluminum Extrusions  Copper-Brass-Bronze

Copper-Brass-Bronze  Nickel

Nickel  Magnets

Magnets  Stainless Steel

Stainless Steel  Stainless Steel Tubing

Stainless Steel Tubing  Steel Service Centers

Steel Service Centers  Titanium

Titanium  Tungsten

Tungsten  Wire Rope

Wire Rope