What is Welder ?

A welder (also weldor, which term distinguishes the tradesman from the equipment used to make welds) is a tradesman who specializes in welding materials together. The materials to be joined can be metals (such as steel, aluminum, brass, stainless steel etc.) or varieties of plastic or polymer. Welders typically have to have good dexterity and attention to detail, as well as some technical knowledge about the materials being joined and best practices in the field.

Welding, without the proper precautions appropriate for the process, can be a dangerous and unhealthy practice. However, with the use of new technology and proper protection, the risks of injury and death associated with welding can be greatly reduced.[citation needed] Because many common welding procedures involve an open electric arc or flame, the risk of burns is significant. To prevent them, welders wear personal protective equipment in the form of heavy leather gloves and protective long sleeve jackets to avoid exposure to extreme heat and flames.

Additionally, the brightness of the weld area leads to a condition called arc eye in which ultraviolet light causes the inflammation of the cornea and can burn the retinas of the eyes. Full face welding helmets with dark face plates are worn to prevent this exposure, and in recent years, new helmet models have been produced that feature a face plate that self-darkens upon exposure to high amounts of UV light. To protect bystanders, opaque welding curtains often surround the welding area. These curtains, made of a polyvinyl chloride plastic film, shield nearby workers from exposure to the UV light from the electric arc, but should not be used to replace the filter glass used in helmets.

Welder under Working of Welding

Welders are also often exposed to dangerous gases and particulate matter. Processes like flux-cored arc welding and shielded metal arc welding produce smoke containing particles of various types of oxides, which in some cases can lead to medical conditions like metal fume fever. The size of the particles in question tends to influence the toxicity of the fumes, with smaller particles presenting a greater danger. Additionally, many processes produce fumes and various gases, most commonly carbon dioxide and ozone, that can prove dangerous if ventilation is inadequate. Furthermore, because the use of compressed gases and flames in many welding processes pose an explosion and fire risk, some common precautions include limiting the amount of oxygen in the air and keeping combustible materials away from the workplace.Welders with expertise in welding pressurized vessels, including submarine hulls, industrial boilers, and power plant heat exchangers and boilers, are generally referred to as boilermakers.

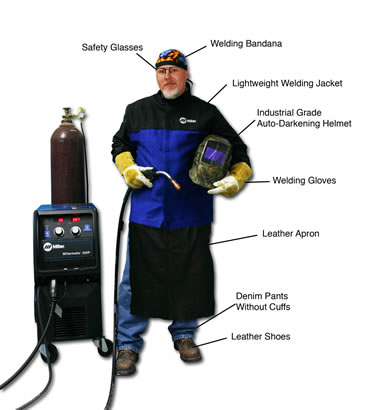

The Well-Dressed Welder

Arc welding produces sparks and emits intense visible and invisible rays that pose several hazards to unprotected skin and eyes. When welding, adequately protect your skin. Shorts, short sleeves, open collars all leave you vulnerable to burns from both flying sparks and the arc rays. Wear only flame-resistant clothing, and button your cuffs and pockets to prevent them from catching sparks. Pants cuffs, too, can catch sparks and should be avoided. With respect to footwear, high top leather shoes offer the best protection.

Personal protective means and devices : Gloves - made of leather, cloth, latex, nitric and PVC, for garden, for home use, for welding. Helmets - glasses, antiphons, shields for welders, security lens. Height protecting means and devices - belts, snap hooks. Breath protection - respirators, masks with changeable filters, filters. Working clothes and protective clothes

Tennis shoes and other cloth shoes are inadequate they can catch a spark and smolder unnoticed and their components can melt and stick to your skin. Always wear proper gloves when welding or handling recently welded material to protect yourself from sparks, arc burns and the heat from the workpiece. Remember, even a quick tack weld requires the use of a welding helmet and appropriate apparel. Although the above sounds obvious, a common fault among welders is not wearing the right safety equipment. While expediency is one reason often given, some welders complain that the common, one-size-fits-all apparel is too bulky, heavy and restricting and that gloves, especially in TIG applications, do not provide the necessary sensitivity and flexibility.

Helmets

Even a brief exposure to the arc’s radiation may be damaging to your eyes, causing symptoms from a burning sensation to temporary blindness. Repeated exposure can lead to permanent injury. Always wear proper eye protection when welding or when exposed to a welding arc.

All auto-darkening helmets must meet ANSI standards, the most recent being ANSI Z87.1-2003. When an arc triggers the sensors on an auto-darkening helmet, the lens darkens in a fraction of a second. Some fixed-shade auto-darkening helmets darken to a #10 shade with a reaction time of 1/2000 to 1/3,600 of a second and are not adequate for frequent tack welds, TIG welding and other industrial applications. Industrial grade helmets react at speeds of 1/10,000 of a second or higher to prevent eye fatigue and arc flash symptoms, and have adjustable shades settings of #9-#12 or #13.

Welder Helmet

Adjustable sensitivity is useful when welding at low amperages, especially TIG, when the light isn’t as bright as other processes. Adjustable delay controls how long the lens remains darkened after the arc stops. When tack welding, a short delay may be desired, while a longer delay may be desirable after welding at very high temperatures. Even when not activated, the lens provides UV/IR protection and usually has a light state of a #3 or #4 shade, which is relatively easy to see through.

Auto-darkening helmets provide some other important benefits also. With a fixed-shade helmet, the welder positions the gun, torch or electrode and then jerks his head down to bring the helmet into place. This may lead to neck injury through the repeated motion, especially for welders who perform a series of tack welds. For the novice or person who welds infrequently, the jerking action can cause him to move out of position and lead to a weld defect. An auto-darkening helmet allows the welder to keep the helmet in place while positioning the electrode, leading to better positioning and relieving some of the stress from the welder’s neck.

Work Environment

You must also protect others in the welding area. Use a weld screen to ensure passersby will not be subjected to the arc flash. Keep your work area free from clutter. This promotes safety and helps increase efficiency by making necessary equipment easier to find. Remove rags, paper or anything else that could be a fire hazard. Cables and hoses can create a tripping hazard. Organize the workspace to minimize the number of cables underfoot and position them so they are not in danger of being run over.

If possible, suspend hoses off the ground and coil up excess hose to prevent kinks and tangles. MIG welding with a wire feeder that allows remote control of the power source is one way to free up space in the welding cell. Examine hoses regularly for leaks, wear and loose connections. To check for leaks, immerse pressured hoses in water (bubbles will indicate leaks.) Repair a leaky or worn hose by cutting out damaged area and splicing. Do NOT use tape.

Avoid working in wet conditions, since water conducts electricity, and insulate yourself from the work and the ground by standing on a dry rubber mat or similar non-flammable material. Connect the workpiece to a proper earth ground and connect the frames of all electrically powered machines to a properly grounded disconnect switch, receptacle or other appropriate ground. Always double-check the installation and verify proper grounding.

You might also like

| Welding Procedure A Welding Procedure Specification (WPS)... | Underwater Welding Underwater welding is a type of welding... | What is TIG WELDING ? Gas tungsten arc welding (GTAW), also known... | Nanomedicine - the Future Medicine Nanomedicine is the medical application of... |

Alloy Suppliers

Alloy Suppliers

Aluminum

Aluminum

Aluminum Extrusions

Aluminum Extrusions

Copper-Brass-Bronze

Copper-Brass-Bronze

Nickel

Nickel

Magnets

Magnets

Stainless Steel

Stainless Steel

Stainless Steel Tubing

Stainless Steel Tubing

Steel Service Centers

Steel Service Centers

Titanium

Titanium

Tungsten

Tungsten

Wire Rope

Wire Rope