What are Plutonium Alloys ?

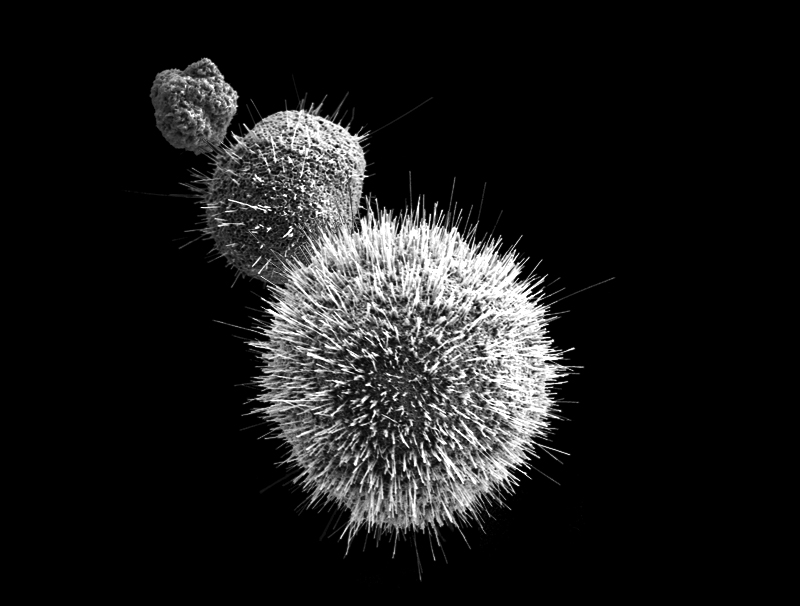

Plutonium is a transuranic radioactive chemical element with the chemical symbol Pu and atomic number 94. It is an actinide metal of silvery-gray appearance that tarnishes when exposed to air, forming a dull coating when oxidized. The element normally exhibits six allotropes and four oxidation states. It reacts with carbon, halogens, nitrogen and silicon.

Plutonium

When exposed to moist air, it forms oxides and hydrides that expand the sample up to 70% in volume, which in turn flake off as a powder that can spontaneously ignite. It is also radioactive and can accumulate in the bones. These properties make the improper handling of plutonium dangerous.

Plutonium is the heaviest primordial element by virtue of its most stable isotope, plutonium-244, whose half-life of about 80 million years is just long enough for the element to be found in trace quantities in nature. Plutonium is also a byproduct of nuclear fission in reactors: Some of the neutrons released by the fission process convert uranium-238 nuclei into plutonium.The most important isotope of plutonium is plutonium-239, with a half-life of 24,100 years. Plutonium-239 is the isotope most useful for nuclear weapons. Plutonium-239 and 241 are fissile, meaning the nuclei of their atoms can split when bombarded by thermal neutrons, releasing energy, gamma radiation and more neutrons. These neutrons can sustain a nuclear chain reaction, leading to applications in nuclear weapons and nuclear reactors.

Plutonium, like most metals, has a bright silvery appearance at first, much like nickel, but it oxidizes very quickly to a dull gray, although yellow and olive green are also reported. At room temperature plutonium is in its ? form (alpha). This, the most common structural form of the element (allotrope), is about as hard and brittle as grey cast iron unless it is alloyed with other metals to make it soft and ductile. Unlike most metals, it is not a good conductor of heat or electricity.

Plutonium Ingot

It has a low melting point (640 °C) and an unusually high boiling point (3,327 °C). Plutonium was first synthesized in 1940 by a team led by Glenn T. Seaborg and Edwin McMillan at the University of California, Berkeley laboratory by bombarding uranium-238 with deuterons. Trace amounts of plutonium were subsequently discovered in nature. Producing plutonium in useful quantities for the first time was a major part of the Manhattan Project during World War II, which developed the first atomic bombs.

The first nuclear test, “Trinity” (July 1945), and the second atomic bomb used to destroy a city (Nagasaki, Japan, in August 1945), “Fat Man”, both had cores of plutonium-239. Human radiation experiments studying plutonium were conducted without informed consent, and a number of criticality accidents, some lethal, occurred during and after the war.

Plutonium-238 has a half-life of 88 years and emits alpha particles. It is a heat source in radioisotope thermoelectric generators, which are used to power some spacecraft. Plutonium-240 has a high rate of spontaneous fission, raising the neutron flux of any sample it is in. The presence of plutonium-240 limits a sample’s usability for weapons or reactor fuel, and determines its grade. Plutonium isotopes are expensive and inconvenient to separate, so particular isotopes are usually manufactured in specialized reactors.

Plutonium-gallium alloy (Pu-Ga) is an alloy of plutonium and gallium, used in nuclear weapon pits – the component of a nuclear weapon where the fission chain reaction is started. Metallic plutonium has several different solid allotropes. The preferred alloy is 3.0–3.5 mol.% (0.8–1.0 wt.%) gallium. More modern pits are produced by casting.

Nuclear Bomb

However, the phase change is useful during the operation of a nuclear weapon. Gallium tends to segregate in plutonium, causing “coring” – gallium-rich centers of grains and gallium-poor grain boundaries. The time to achieve homogenization of gallium increases with increasing grain size of the alloy and decreases with increasing temperature. Two stabilizing elements were considered, silicon and aluminium. However, only aluminium produced satisfactory alloys. There are several plutonium and gallium intermetallic compounds : PuGa, Pu3Ga, and Pu6Ga.

Addition of 7.5 wt.% of plutonium-238, which has significantly faster decay rate, to the alloy increases the aging damage rate by 16 times, assisting with plutonium aging research. The Blue Gene supercomputer aided with simulations of plutonium aging processes. Presence of gallium in plutonium signifies its origin from weapon plants or decommissioned nuclear weapons. For reprocessing of surplus warhead pits into MOX fuel, the majority of gallium has to be removed as its high content could interfere with the fuel rod cladding (gallium attacks zirconium and with migration of fission products in the fuel pellets.

In the ARIES process, the pits are converted to oxide by converting the material to plutonium hydride, then optionally to nitride, and then to oxide. Gallium is then mostly removed from the solid oxide mixture by heating at 1100°C in a 94% argon 6% hydrogen atmosphere, reducing gallium content from 1% to 200 ppm. Further dilution of plutonium oxide during the MOX fuel manufacture brings gallium content to levels considered negligible. Electrorefining is another way to separate gallium and plutonium.

For weapons use, the plutonium pit parts have to be coated with a layer of another metal. Subsequent pits were coated with nickel, by exposing the plutonium parts to nickel tetracarbonyl gas, which reacts with the plutonium surface and deposits a thin layer of nickel. Plutonium alloys can be produced by adding a metal to molten plutonium.

You might also like

| What is Yellow Cake Uranium? Uranium Yellow Cake Yellowcake (also called... | What is Scrap Metal ? Scrap Metal Scrap is a term used to describe... | Copper Nanoparticles What are Copper Nanoparticles ? Copper (Cu)... | Aluminum alloys What is Aluminum Alloys ? Aluminium alloys... |

Alloy Suppliers

Alloy Suppliers

Aluminum

Aluminum

Aluminum Extrusions

Aluminum Extrusions

Copper-Brass-Bronze

Copper-Brass-Bronze

Nickel

Nickel

Magnets

Magnets

Stainless Steel

Stainless Steel

Stainless Steel Tubing

Stainless Steel Tubing

Steel Service Centers

Steel Service Centers

Titanium

Titanium

Tungsten

Tungsten

Wire Rope

Wire Rope