MIG Welding - Overview

MIG welding is an abbreviation for Metal Inert Gas Welding. It is a process developed in the 1940’s, and is considered semi-automated. This means that the welder still requires skill, but that the MIG welding machine will continuously keep filling the joint being welded. MIG welding can be used on all thicknesses of steels, on aluminum, nickel, and even on stainless steel, etc. However, it is most typically utilized in manufacturing and in commercial fabrication settings.

MIG welding is an abbreviation for Metal Inert Gas Welding

MIG welding is an abbreviation for Metal Inert Gas Welding

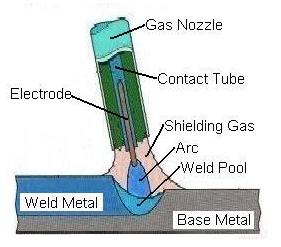

Metal Inert Gas (MIG) welding, also sometimes called Gas Metal Arc Welding (GMAW) is a process that was developed in the 1940s for welding aluminum and other non-ferrous metals. MIG welding is an automatic or semi-automatic process in which a wire connected to a source of direct current acts as an electrode to join two pieces of metal as it is continuously passed through a welding gun. A flow of an inert gas, originally argon, is also passed through the welding gun at the same time as the wire electrode. This inert gas acts as a shield, keeping airborne contaminants away from the weld zone.

The primary advantage of MIG welding is that it allows metal to be welded much more quickly than traditional “stick welding” techniques. This makes it ideal for welding softer metals such as aluminum. When this method was first developed, the cost of the inert gas made the process too expensive for welding steel. Over the years, the process has evolved, however, and semi-inert gases such as carbon dioxide can now be used to provide the shielding function, which now makes MIG welding cost-effective for welding steel.

MIG equipment consists of a welding gun, a power supply, a shielding gas supply, and a wire-drive system which pulls the wire electrode from a spool and pushes it through a welding gun. A source of cooling water may be required for the water cooled welding gun. There are also Mig rod ovens for proper storage of electrodes.

The majority of MIG welding applications require direct current, reverse polarity. This type of electrical connection yields a stable arc, helps to smooth the metal transfer, has relatively low spatter loss, and gives good weld bead characteristics. Direct current straight polarity (electrode negative) is seldom used, since the arc can become unstable and erratic even though the electrode-melting rate is higher.

MIG Welding Basic Principle

Alternating current has found no commercial acceptance with MIG welding because the arc is extinguished during each half cycle as the current reduces to zero and it may not re-ignite if the cathode cools sufficiently. MIG guns are available for manual manipulation, semiautomatic welding, and for machine or automatic welding. Because the electrode is fed continuously, a welding gun must have a sliding electrical contact to transmit the welding current to the electrode. The gun must also have a gas passage and a nozzle to direct the shielding gas around the arc and the molten weld pool.

An electrical switch is used to start and stop the welding current, electrode feed, and the shielding gas flow. Selecting air or water-cooled guns is based on the type of shielding gas, welding current range, materials, weld joint design, and existing shop practice and conditions. Air-cooled guns are usually limited to work using 200 amperes or less. Water-cooled guns are usually used for applications requiring 200 to 750 amperes. The water lines in a water cooled gun adds weight and reduces maneuverability of the gun for welding. When it was first developed it was called (GMA) Gas Metal Arc.

MIG welding unlike most other welding processes has one standard voltage type and polarity type. Direct current flows in one direction, from the negative (-) to the positive (+). The power source used for MIG welding is called a “constant voltage power supply”. In MIG welding the voltage is what is controlled and adjusted. When comparing MIG welding to Arc or TIG welding, MIG welding machines use voltage settings to set the machine. TIG and Arc welding machines use amperage to set the machine or a “constant amperage power supply”.

MIG welders consist of a handle with a trigger controlling a wire feed, feeding the wire from a spool to the weld joint. The wire is similar to an endless bicycle brake cable. The wire runs through the liner, which also has a gas feeding through the same cable to the point of arc, which protects the weld from the air.

Advantages of MIG welding are:

- High quality welds can be produced much faster

- Since a flux is not used, there is no chance for the entrapment of slag in the weld metal resulting in high quality welds

- The gas shield protects the arc so that there is very little loss of alloying elements. Only minor weld spatter is produced

- MIG welding is versatile and can be used with a wide variety of metals and alloys

- The MIG process can be operated several ways, including semi and fully automatic

- It produces long, continuous welds much faster than traditional welding methods.

- Since the shielding gas protects the welding arc, this type of welding produces a clean weld with very little splatter.

- It can be used with a wide variety of metals and alloys.

- The MIG welding cannot be used in the vertical or overhead welding positions because of the high heat input and the fluidity of the weld puddle

- The equipment is complex.

- The equipment is quite complex, as MIG welding requires a source of direct current, a constant source and flow of gas, as well as the continuously moving wire electrode. Plus, electrodes are available in a wide range of sizes and are made from a number of metal types to match the welding application.

- The actual technique used is different from traditional welding practices, so there is learning curve associated with MIG welding, even for experienced welders. For example, MIG welders need to push the welding puddle away from them and along the seam.

- The necessity for the inert gas shield means that MIG welding cannot be used in an open area where the wind would blow away the gas shield.

Gas for MIG welding is what makes MIG welding possible. The name informs us of this; “Metal Inert Gas welding”. The gasses used are what shield the weld from oxygen in the air. When Carbon Dioxide or Oxygen is added to the mixture, MIG welding is not technically MIG welding anymore. This is due to the fact that both Carbon Dioxide and Oxygen are not inert gasses. The process then becomes GMAW or Gas Metal Arc Welding.

The type of gas uses also determines :

- How deep the weld penetrates the metal welded

- The characteristics of the welding arc

- The mechanical properties of the weld.

When choosing the type of gas to be used, it is best to seek input from a welding supply store. The store will recommend the proper gas to match the welding wire to be used. Or, one may utilize the welding wire manufacturer’s recommendation. Typically, the manufacturer will provide a few choices ranging from the best choice, to something that will provide the minimum acceptable results. The final choice in the type of gas, is based on cost.

The four most common gasses used are :

- Argon

- CO2 / Carbon Dioxide

- O2 / Oxygen

- Helium (the least common)

Most of the times these gasses are used in a mixture form, typically consisting of carbon dioxide, and Argon or Oxygen. Oxygen is what causes most weld defects, however, in small percentages, mixed with other gasses, it improves the arc characteristics. Argon and Carbon Dioxide can be used by themselves. In some case there is tri-mix shielding gas containing Argon, Carbon dioxide, and Helium.

The more common mixtures and gasses are :

- C2 or 2% Carbon Dioxide and 98% Argon

- C25 or 25% Carbon Dioxide and 95% Argon

- 100% Carbon Dioxide

- 100% Argon

Welding of carbon steel can be done with Carbon Dioxide alone and it produces the deepest penetration, the most smoke and the roughest weld. A mixture of gasses ranging from 2% to 25% Carbon Dioxide and the rest Argon can be used. However, a higher percent of Argon will result in a smoother, better looking weld, and improves the arc characteristics.

Welding of stainless steel is typically done with C2 or 2% Carbon Dioxide and 98% Argon. In some cases there is tri-mix shielding gas containing 90% Helium, 7.5% Argon, and 2.5%Carbon dioxide. Welding of aluminum is typically done with Argon alone, with one exception. If the aluminum being welded is thicker then ½ of an inch there may be Helium added to the mix.

MIG welding is a welding process that can weld almost any metal. It may not always be the best choice for weld quality but MIG welding is a fast, cost efficient, and produces results that are more than acceptable for most manufacturing and fabrication needs! Not everybody is building a space station.

The three most common metals welded with a MIG welder are:

- Carbon steel.

- Stainless steel.

- Aluminum, with a special feeder because aluminum wire is very soft.

Carbon steel welds are almost flawlessly done with a MIG welder. There are very few problems, beside the downside of the design of a MIG welding machine. The wire stiffness is just right to pass through the liner from the machine with minimal friction to cause problems and has enough stiffness to be feed without coiling up. Depending on how much voltage the MIG welding machine is running at, the weld can be set to one of three transfer types, short circuit, globular, or spray.

Stainless steel MIG welding does not require any special equipment. In the case of welding stainless steel, the biggest problem comes from the cord or liner of the welder. The trick when welding stainless steel is to keep the cord as straight as possible. Otherwise, the wire feed that feeds the weld joint will have too much friction due to stainless steel being stiffer then carbon steel. Think of trying to shove a wire hanger through a bent garden hose. Chances are if the hose is straight you can easily put it through. If the hose is bent, you will have difficulty.

Aluminum MIG welding usually requires a double feed, referred to as, (a push and pull method). That is a spool of wire is pushed through the MIG handle and the handle itself has a pulley that pulls the wire. Welding aluminum is not very common for MIG welding. It is typically done when high production is needed.The first picture below is a double rollers push feed on a Millermatic 350P MIG Machine. The second and third pictures below are the bottom view, and top view of a Python pull feed gun.

You might also like

| Welding Procedure A Welding Procedure Specification (WPS)... | What is TIG WELDING ? Gas tungsten arc welding (GTAW), also known... | Underwater Welding Underwater welding is a type of welding... | Welding Welding is a fabrication or sculptural process... |

Alloy Suppliers

Alloy Suppliers

Aluminum

Aluminum

Aluminum Extrusions

Aluminum Extrusions

Copper-Brass-Bronze

Copper-Brass-Bronze

Nickel

Nickel

Magnets

Magnets

Stainless Steel

Stainless Steel

Stainless Steel Tubing

Stainless Steel Tubing

Steel Service Centers

Steel Service Centers

Titanium

Titanium

Tungsten

Tungsten

Wire Rope

Wire Rope