Indium tin oxide (ITO, or tin-doped indium oxide) is a solid solution of indium(III) oxide (In2O3) and tin(IV) oxide (SnO2), typically 90% In2O3, 10% SnO2 by weight.

Indium Tin Oxide

Indium Tin Oxide

As with all transparent conducting films, a compromise must be made between conductivity and transparency, since increasing the thickness and increasing the concentration of charge carriers will increase the material’s conductivity, but decrease its transparency.

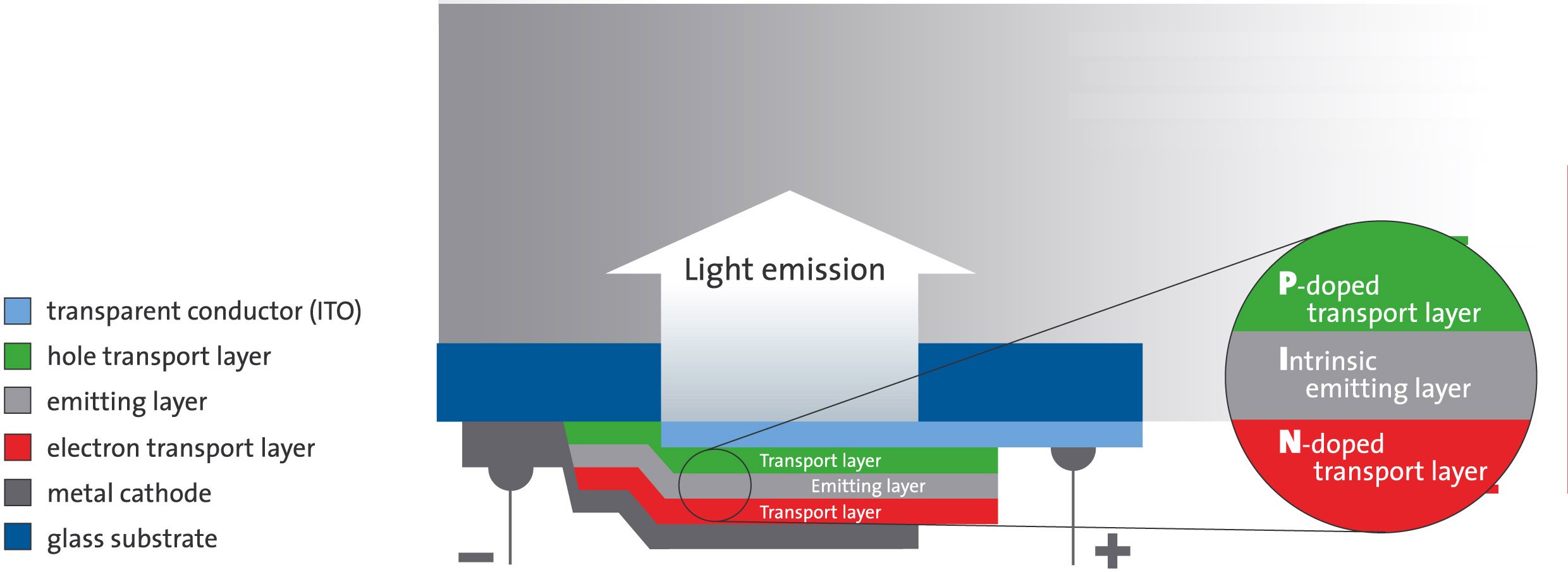

In an organic light-emitting diode (OLED), holes and electrons are injected into a stack of organic layers, which are usually sandwiched between a transparent indium tin oxide (ITO) electrode and a metal electrode. Electrons and holes recombine in the emission zone of the device, which contains organic emitter dyes. Here, excitons are formed by the combining charge carriers, which eventually decay and emit as visible light.

In an organic light-emitting diode (OLED), holes and electrons are injected into a stack of organic layers, which are usually sandwiched between a transparent indium tin oxide (ITO) electrode and a metal electrode. Electrons and holes recombine in the emission zone of the device, which contains organic emitter dyes. Here, excitons are formed by the combining charge carriers, which eventually decay and emit as visible light.

Thin films of indium tin oxide are most commonly deposited on surfaces by electron beam evaporation, physical vapor deposition, or a range of sputter deposition techniques.

You might also like

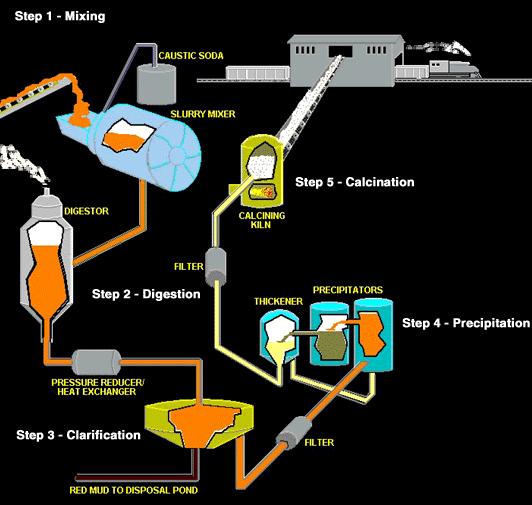

| Semiconductor Materials A semiconductor is a substance,... | The Bayer and Hall-Heroult Process Aluminum manufacture is accomplished... | Corrosion Corrosion is the disintegration of an engineered... | What is Diamond? Diamond is less stable than graphite,... |

Alloy Suppliers

Alloy Suppliers

Aluminum

Aluminum

Aluminum Extrusions

Aluminum Extrusions

Copper-Brass-Bronze

Copper-Brass-Bronze

Nickel

Nickel

Magnets

Magnets

Stainless Steel

Stainless Steel

Stainless Steel Tubing

Stainless Steel Tubing

Steel Service Centers

Steel Service Centers

Titanium

Titanium

Tungsten

Tungsten

Wire Rope

Wire Rope