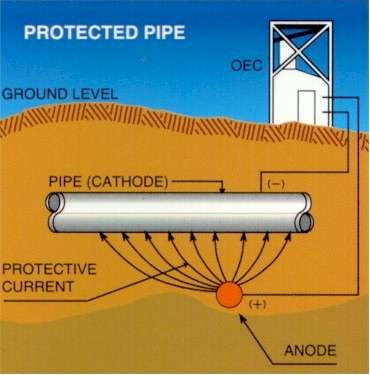

Cathodic Protection

The basic concept of cathodic protection is that the electrical potential of the subject metal is reduced below its corrosion potential, and that it will then be incapable of going into solution, or corroding.

Indeed the principles of corrosion reactions are used in the design and construction of expendable and re-chargeable batteries and accumulators which play such a major part in modern life. Likewise a car battery on charge does not corrode, in fact in this case the reaction is reversible, and energy is ‘pumped back in’.

You might also like

| Anti Corrosion What is Rust Inhibitor ? Anti-corrosion... | Zinc Alloys What is Zinc Alloy ? Zinc Alloys are combinations... | Hydrogen Embrittlement Hydrogen Embrittlement - Definition and Meaning When... | Corrosion Stainless Steel How can stainless steel corrode? All "stainless"... |

Alloy Suppliers

Alloy Suppliers

Aluminum

Aluminum

Aluminum Extrusions

Aluminum Extrusions

Copper-Brass-Bronze

Copper-Brass-Bronze

Nickel

Nickel

Magnets

Magnets

Stainless Steel

Stainless Steel

Stainless Steel Tubing

Stainless Steel Tubing

Steel Service Centers

Steel Service Centers

Titanium

Titanium

Tungsten

Tungsten

Wire Rope

Wire Rope