Forming Processes of Metal

are introduced through the application of external forces to the workpiece, these forces being in equilibrium. With the application of load to the workpiece, internal stress and displacements are generated causing shape distortions. If the loads are low, then with the release of the loads, the internal stresses will disappear and the workpiece will be restored to its original shape. It is then said that the applied loads were elastic and so were the stresses and strains. Elastic strains are recoverable on release of the loads.

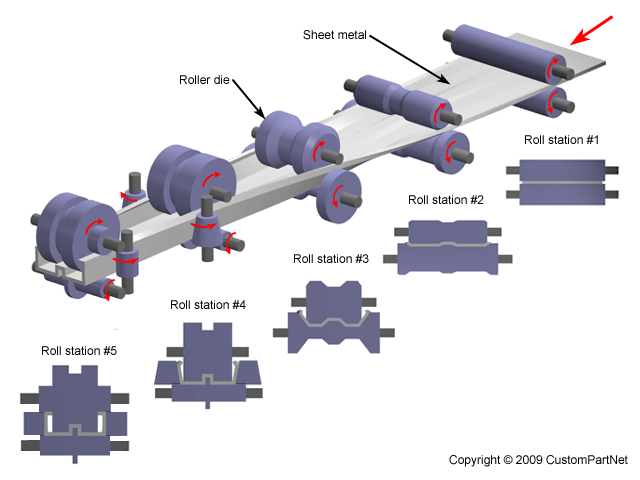

Roll Metal Forming Processing

Roll Metal Forming Processing

When the loads are high enough, the changes in shape will not disappear after the load is released. The changes in shape and the strain, those that did not disappear, namely, the permanent ones, are called plastic deformations. The loads causing plastic deformations are said to have surpassed the elastic limit. During metal forming by bulk plastic deformations (to be defined), the plastic deformations are much larger than the elastic deformations, which in general are ignored.

You might also like

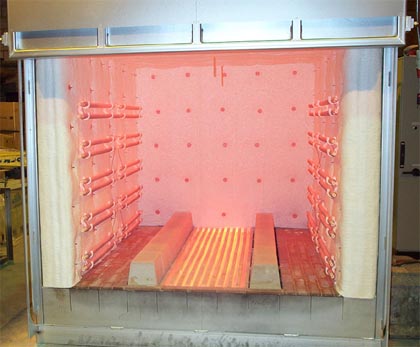

| Deep Drawing What is Deep Drawing ? Deep drawing manufacturing... | There are various methods of forming... | Transport Phenomena In engineering and physics, the study of... | Heat Treatment Furnaces Heat treating is a group of industrial and... |

Alloy Suppliers

Alloy Suppliers

Aluminum

Aluminum

Aluminum Extrusions

Aluminum Extrusions

Copper-Brass-Bronze

Copper-Brass-Bronze

Nickel

Nickel

Magnets

Magnets

Stainless Steel

Stainless Steel

Stainless Steel Tubing

Stainless Steel Tubing

Steel Service Centers

Steel Service Centers

Titanium

Titanium

Tungsten

Tungsten

Wire Rope

Wire Rope