Precipitation Hardening Overview

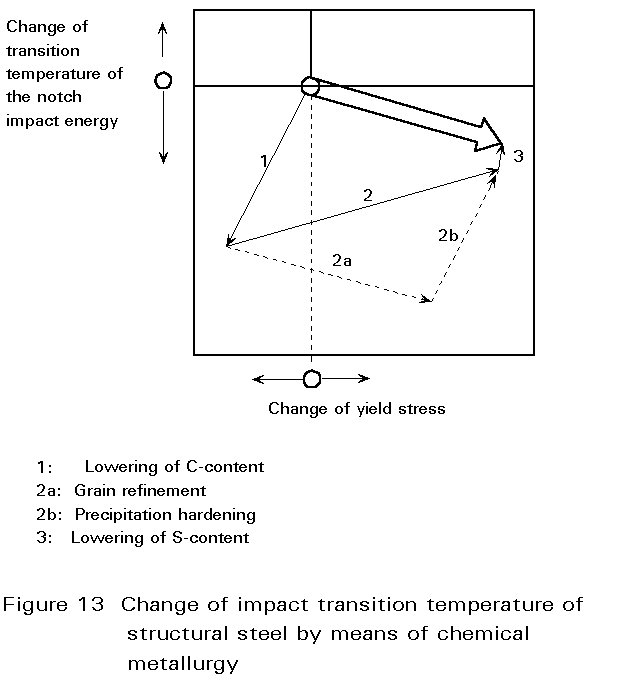

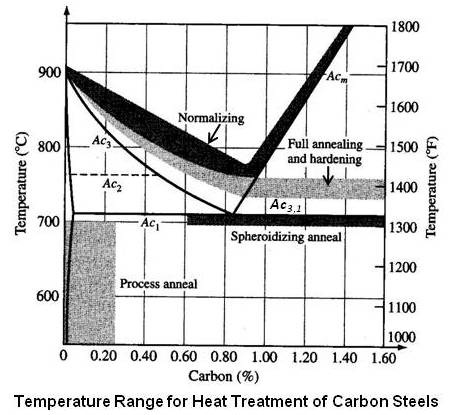

Precipitation hardening also called age hardening, is a heat treatment technique used to increase the yield strength of malleable materials, including most structural alloys ofaluminium, magnesium, nickel, titanium, and some stainless steels. Precipitation hardening relies on changes in solid solubility with temperature to produce fine particles of an impurity phase, which impede the movement of dislocations, or defects in a crystal’s lattice. Unlike ordinary tempering, alloys must be kept at elevated temperature for hours to allow precipitation to take place. This time delay is called aging.

Note that two different heat treatments involving precipitates can alter the strength of a material: solution heat treating and precipitation heat treating. Solid solution strengtheninginvolves formation of a single-phase solid solution via quenching. Precipitation heat treating involves the addition of impurity particles to increase a material’s strength. Precipitation hardening via precipitation heat treatment is the main topic of discussion in this article.

You might also like

| Heat Treatment Furnaces Heat Treatment Furnaces of Steel Heat treating... | Optimal Combination of STRENGTH and TOUGHNESS Optimal Combination of STRENGTH and TOUGHNESS Preceding... | Aluminum “Hardening” - How it works? Heat Treatment of Aluminum The term “heat... | Do you know Heat Treatment process ? Heat Treatment Heat Treatment is the controlled... |

Alloy Suppliers

Alloy Suppliers

Aluminum

Aluminum

Aluminum Extrusions

Aluminum Extrusions

Copper-Brass-Bronze

Copper-Brass-Bronze

Nickel

Nickel

Magnets

Magnets

Stainless Steel

Stainless Steel

Stainless Steel Tubing

Stainless Steel Tubing

Steel Service Centers

Steel Service Centers

Titanium

Titanium

Tungsten

Tungsten

Wire Rope

Wire Rope