Aerospace alloys

The addition of scandium to aluminium creates nanoscale Al3Sc precipitates which limit the excessive grain growth that occurs in the heat-affected zone of welded aluminium components. This has two beneficial effects: the precipitated Al3Sc forms smaller crystals than are formed in other aluminium alloys and the width of precipitate-free zones that normally exist at the grain boundaries of age-hardenenable aluminium alloys is reduced.

Parts of the Mig–29 are made from Al-Sc alloy

Parts of the Mig–29 are made from Al-Sc alloy

Scandium is also a potent grain refiner in cast aluminium alloys, and atom for atom, the most potent strengthener in aluminium, both as a result of grain refinement and precipitation strengthening. However, titanium alloys, which are stronger but heavier, are cheaper and much more widely used.

The main application of metallic scandium by weight is in aluminium-scandium alloys for minor aerospace industry components. These alloys contain between 0.1% and 0.5% (by weight) of scandium. They were used in the Russian military aircraft Mig 21 and Mig 29. Some items of sports equipment, which rely on high performance materials, have been made with scandium-aluminium alloys, including baseball bats , lacrosse sticks, as well as bicycle[12] frames and components, and tent poles. U.S. gunmaker Smith & Wesson produces revolvers with frames composed of scandium alloy and cylinders of titanium.

The following aluminium alloys are commonly used in aircraft and other aerospace structures :

- 7068 aluminium

- 7075 aluminium

- 6061 aluminium

- 6063 aluminium

- 2024 aluminium

- 5052 aluminium

Note that the term aircraft aluminium or aerospace aluminium usually refers to 7075.

Marine alloys

These alloys are used for boat building and shipbuilding, and other marine and salt-water sensitive shore applications. 5059 is an aluminium alloy, primarily alloyed with magnesium. It is not strengthened by heat treatment, instead becoming stronger due to strain hardening, or cold mechanical working of the material.

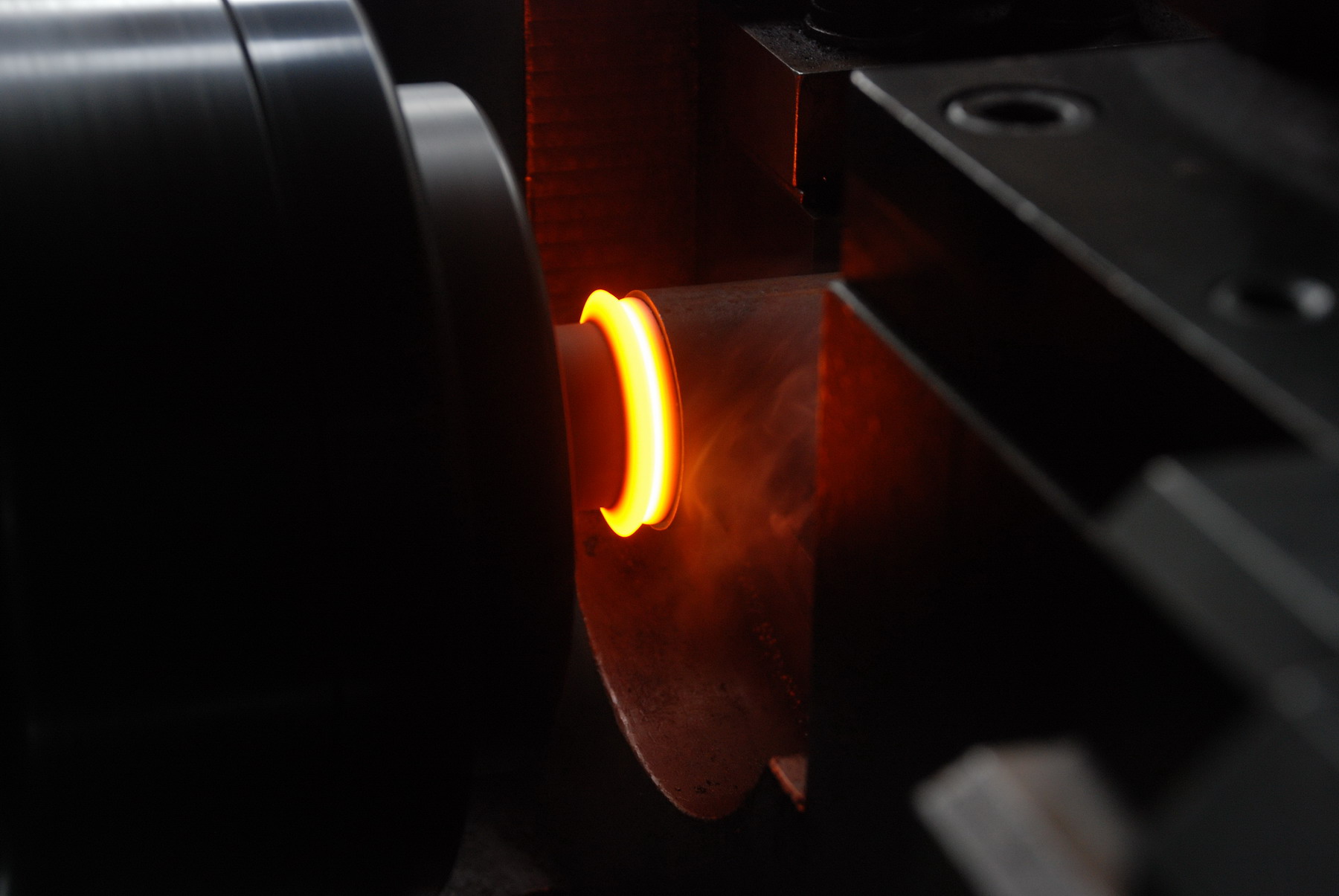

Aluminum propeller alloy

Since heat treatment doesn’t strongly affect the strength, 5059 can be readily welded and retain most of its mechanical strength. 5059 alloy was derived from closely related 5083 aluminium alloy by researchers at Corus Aluminum in 1999.

- 5052 aluminium

- 5059 aluminium

- 5083 aluminium

- 5086 aluminium

- 6061 aluminium

- 6063 aluminium

- 4043, 5183, 6005A, 6082 also used in marine constructions and off shore applications.

Cycling alloys

These alloys are used for cycling frames and components. 6061 is a precipitation hardening aluminium alloy, containing magnesium and silicon as its major alloying elements. Originally called “Alloy 61S” it was developed in 1935. It has good mechanical properties and exhibits good weldability. It is one of the most common alloys of aluminium for general purpose use.

It is commonly available in pre-tempered grades such as 6061-O (solutionized) and tempered grades such as 6061-T6 (solutionized and artificially aged) and 6061-T651 (solutionized, stress-relieved stretched and artificially aged).

- 2014 aluminium

- 6061 aluminium

- 6063 aluminium

- 7005 aluminium

- 7075 aluminium

Automotive alloys

6111 aluminium and 2008 aluminum alloy are extensively used for external automotive body panels, with 5083 and 5754 used for inner body panels. Hoods have been manufactured from 2036, 6016, and 6111 alloys.

Aluminum Alloys Wheel

Truck and trailer body panels have used 5456 aluminum. Automobile frames often use 5182 aluminum or 5754 aluminum formed sheets, 6061 or 6063 extrusions. Wheels have been cast from A365.0 aluminum or formed 5xxx sheet.

You might also like

| Precipitation Hardening Precipitation Hardening Overview Precipitation... | What are Magnesium Alloys ? Magnesium Alloys Magnesium alloys are mixtures... | What is Superalloy ? What is Superalloy ? - Definition and Meaning A... | How does Friction Welding Work ? What is Friction Welding ? Friction welding... |

Alloy Suppliers

Alloy Suppliers

Aluminum

Aluminum

Aluminum Extrusions

Aluminum Extrusions

Copper-Brass-Bronze

Copper-Brass-Bronze

Nickel

Nickel

Magnets

Magnets

Stainless Steel

Stainless Steel

Stainless Steel Tubing

Stainless Steel Tubing

Steel Service Centers

Steel Service Centers

Titanium

Titanium

Tungsten

Tungsten

Wire Rope

Wire Rope