A superalloy, or high-performance alloy, is an alloy that exhibits excellent mechanical strength and creep resistance at high temperatures, good surface stability, and corrosion and oxidation resistance.

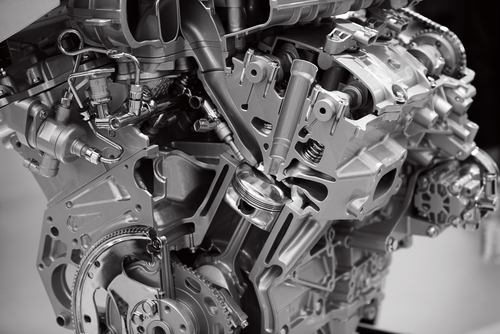

Superalloys at automotive application

Superalloys at automotive application

Superalloys typically have a matrix with an austenitic face-centered cubic crystal structure. A superalloy’s base alloying element is usually nickel, cobalt, or nickel-iron. Typical applications are in the aerospace, industrial gas turbine and marine turbine industry, e.g. for turbine blades for hot sections of jet engines, and bi-metallic engine valves for use in diesel and automotive applications.

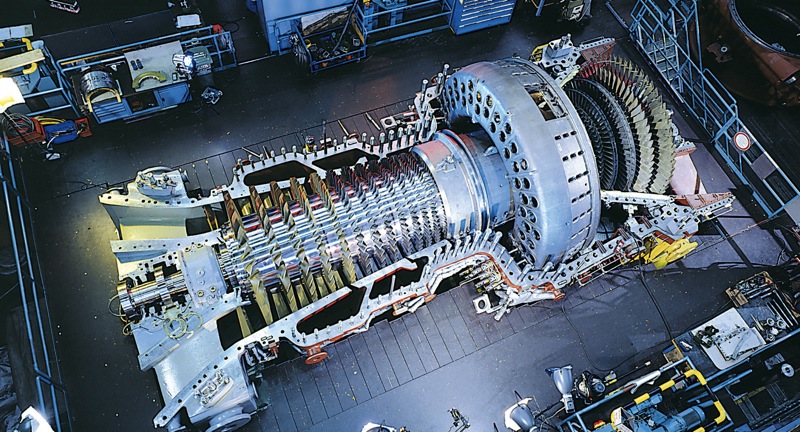

Steam Turbine Blade made from Superalloys

Steam Turbine Blade made from Superalloys

Superalloys are metallic materials for service at high temperatures, particularly in the hot zones of gas turbines. Such materials allow the turbine to operate more efficiently by withstanding higher temperatures. Turbine Inlet Temperature (TIT), which is a direct indicator of the efficiency of a gas turbine engine, depends on the temperature capability of 1st stage high pressure turbine blade made of Ni base superalloys exclusively.

One of the most important superalloy properties is high temperature creep resistance. Other crucial material properties are fatigue life, phase stability, as well as oxidation and corrosion resistance.

Avalloy superalloys are incorporated in Rolls-Royce Trent 900 engines, which power the Airbus A380 Superjumbo (Credit Photo @ Rolls-Royce)

Avalloy superalloys are incorporated in Rolls-Royce Trent 900 engines, which power the Airbus A380 Superjumbo (Credit Photo @ Rolls-Royce)

A superalloy is a generic term for a metal that can operate at very high temperatures, up to about 2000 °F (1100 °C). They are popular for use in the superhot turbine areas of jet engines. They are used for more advanced oxygen-breathing designs, such as the ramjet and scramjet. When we’re flying through the sky in hypersonic craft, we’ll have superalloys to thank for it.

Turbine made from Superaloys

Turbine made from Superaloys

Superalloys develop high temperature strength through solid solution strengthening. In Ni-base superalloys the gamma prime phase [Ni3(Al,Ti)] present acts as a coherent barrier to dislocation motion and is a precipitate strengthener. The gamma prime phase size can be precisely controlled by careful precipitation hardening heat treatments.

Many superalloys have a two phase heat treatment which creates a dispersion of square gamma prime particles known as the primary phase with a fine dispersion between these known as secondary gamma prime. Cobalt base superalloys do not have a strengthening secondary phase like gamma prime.

The historical developments in superalloy processing have brought about considerable increases in superalloy operating temperatures. In the 1940s investment casting of cobalt base alloys significantly raised operating temperatures. Within gas turbine engines many forms of superalloys are present.

Turbine blades can be polycrystalline, have a columnar grain structure, or be a single crystal. Columnar grain structured blades are created using directional solidification techniques and have grains parallel to the major stress axes.

Single-crystal superalloys (SC superalloys) are formed as a single crystal using a modified version of the directional solidification technique, so there are no grain boundaries in the material. Superalloys are commonly used in gas turbine engines in regions that are subject to high temperatures which require high strength, excellent creep resistance, as well as corrosion and oxidation resistance.

In most turbine engines this is in the high pressure turbine where air cooled blades can face temperatures 200°C above the melting temperature of the superalloy used. Turbocharger turbines also use superalloys, typically electron beam welded to a steel shaft. The corrosions resistance is particularly useful when dealing with the high temperatures and pressures found in a diesel engine.

Additional applications of superalloys include: gas turbines (commercial and military aircraft, power generation, and marine propulsion), space vehicles, submarines, nuclear reactors, military electric motors, racing and high performance vehicles, chemical processing vessels, bomb casings and heat exchanger tubing.

Superalloys have high contents of nickel, which is more expensive than iron. The alloying elements and heat-treatments also often make superalloys difficult to machine and weld, increasing fabrication costs, part reject rates, and rework.

The structure of most precipitation strengthened nickel-base superalloys consists of the gamma matrix, and of intermetallic gamma‘ precipitates. The alloying elements are dissolved in the gamma phase as well. The gamma‘ phase hardens the alloy through an unusual mechanism called the yield stress anomaly.

Dislocations dissociate in the gamma‘ phase, leading to the formation of an anti-phase boundary. Superalloy products that are subjected to high working temperatures and corrosive atmosphere (such as high pressure turbine region of jet engines) are coated with various kinds of coating. Mainly two kinds of coating process are applied: pack cementation process and gas phase coating. In most cases, after the coating process near-surface regions of parts are enriched with aluminium, the matrix of the coating being nickel aluminide.

At high temperatures the gaseous aluminium halide is transferred to the surface of the part and diffuses inside (mostly inward diffusion). This process is carried out at higher temperatures, about 1080 °C. The coating mixture contains active coating material and activator, but usually does not contain thermal ballast. This kind of coating also requires diffusion heat treatment.

The bond coat adheres the thermal barrier coating to the superalloy substrate. The Chromium provides oxidation and hot-corrosion resistance. The aluminum controls oxidation mechanisms by limiting oxide growth. About half of the use of superalloys is in applications where the service temperature is close to the melting temperature of the alloy. Future paradigm in alloy development focus on reduction of weight, improving oxidation and corrosion resistance while maintaining the strength of the alloy. Furthermore, with the increasing demand for turbine blade for power generation, another focus of alloy design is to reduces the cost of super alloys.

You might also like

| Nickel and Nickel Alloys Nickel is a chemical element, with... | Aluminum alloy Aluminum Alloy Wheel An alloy is a material... | Copper Alloys Copper is one of the most useful... | Transparent Ceramics Transparent ceramics have recently... |

Alloy Suppliers

Alloy Suppliers

Aluminum

Aluminum

Aluminum Extrusions

Aluminum Extrusions

Copper-Brass-Bronze

Copper-Brass-Bronze

Nickel

Nickel

Magnets

Magnets

Stainless Steel

Stainless Steel

Stainless Steel Tubing

Stainless Steel Tubing

Steel Service Centers

Steel Service Centers

Titanium

Titanium

Tungsten

Tungsten

Wire Rope

Wire Rope