What is Hydrogen cracking ?

Hydrogen cracking also known as cold cracking or delayed cracking. The main feature of this type of crack is that it occurs in ferritic weldable steels, and generally occurs immediately on welding or after a short time after welding, but usually within 48hrs. The mechanism starts with lone hydrogen atoms diffusing through the metal.

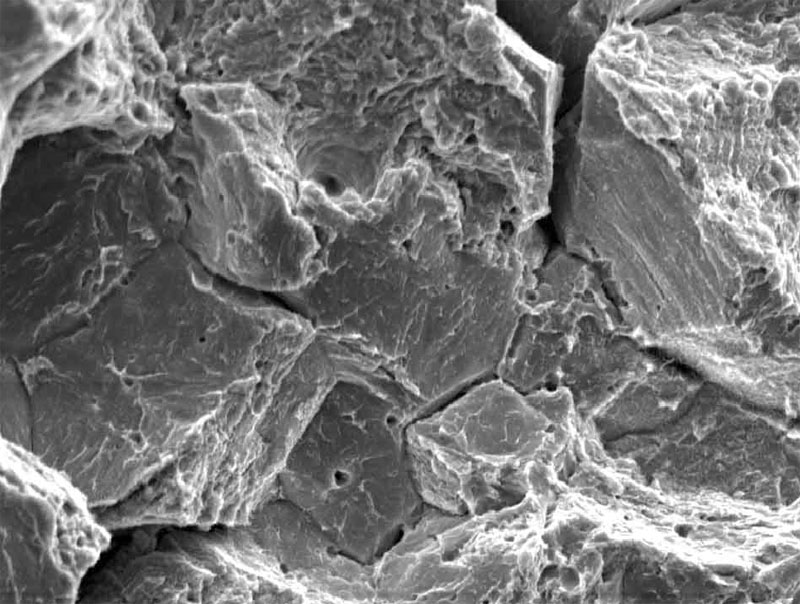

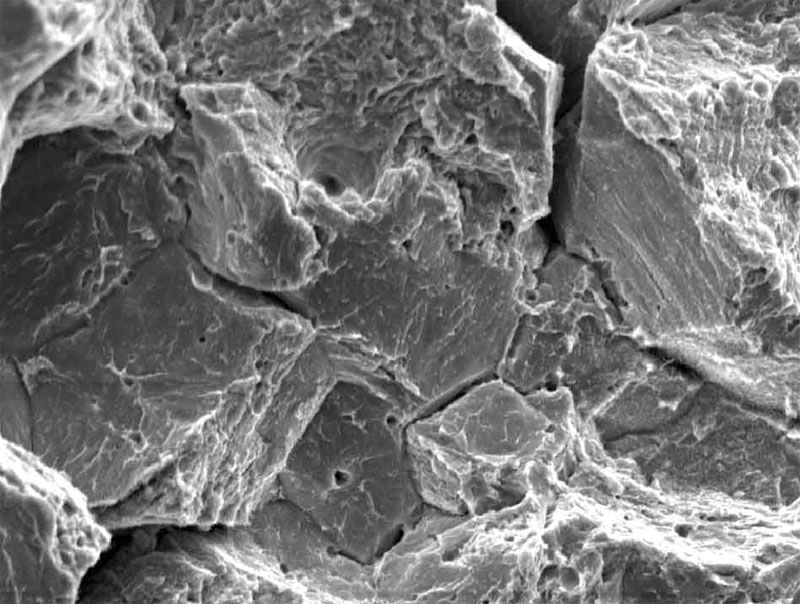

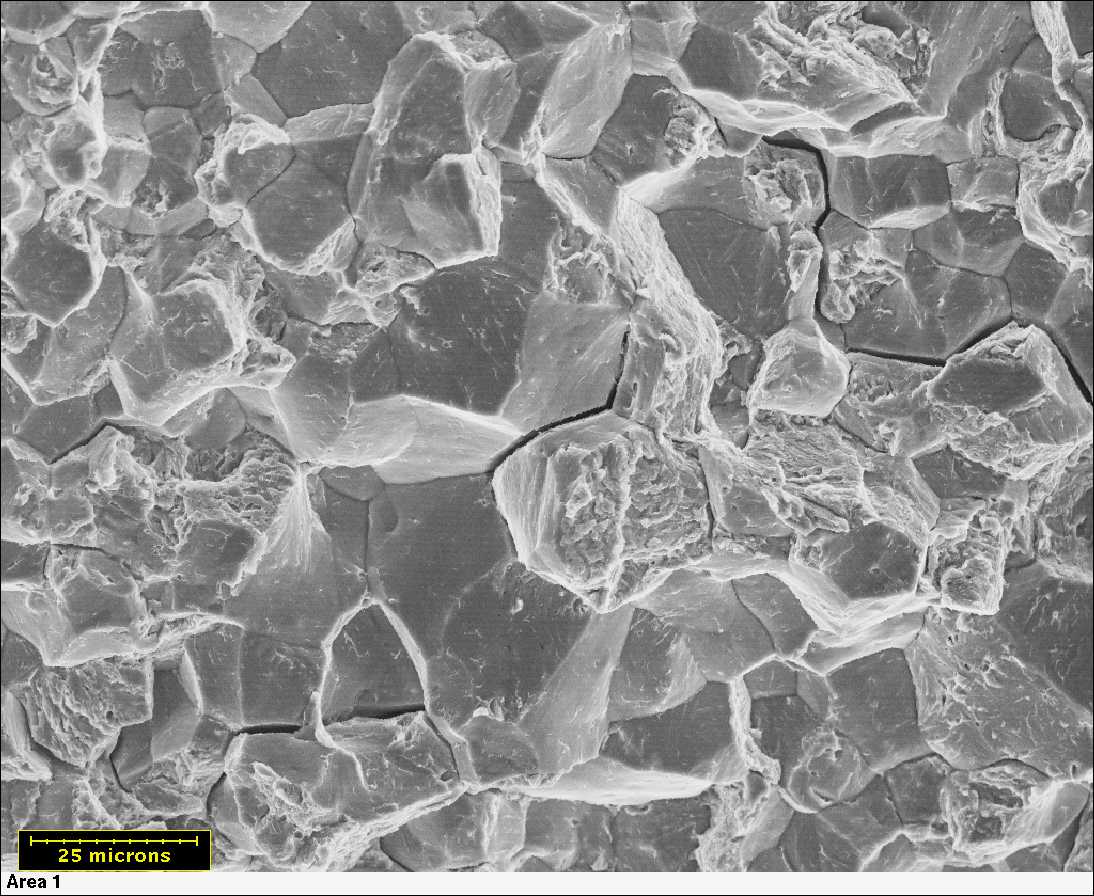

At high temperatures, the elevated solubility of hydrogen allows hydrogen to diffuse into the metal (or the hydrogen can diffuse in at a low temperature, assisted by a concentration gradient). When these hydrogen atoms re-combine in minuscule voids of the metal matrix to form hydrogen molecules, they create pressure from inside the cavity they are in. This pressure can increase to levels where the metal has reduced ductility and tensile strength up to the point where it cracks open (hydrogen induced cracking, or HIC). High-strength and low-alloy steels, nickel and titanium alloys are most susceptible. Austempered iron is also susceptible.

You might also like

| Do you know Hydrogen Embrittlement ? Hydrogen embrittlement Hydrogen embrittlement... | The Phenomenon of Hydrogen Embrittlement Hydrogen Embrittlement Hydrogen embrittlement... | Do you know the Stress Corrosion Cracking ? Stress Corrosion Cracking Stress corrosion... | Hydrogen Embrittlement Hydrogen Embrittlement - Definition and Meaning When... |

Alloy Suppliers

Alloy Suppliers

Aluminum

Aluminum

Aluminum Extrusions

Aluminum Extrusions

Copper-Brass-Bronze

Copper-Brass-Bronze

Nickel

Nickel

Magnets

Magnets

Stainless Steel

Stainless Steel

Stainless Steel Tubing

Stainless Steel Tubing

Steel Service Centers

Steel Service Centers

Titanium

Titanium

Tungsten

Tungsten

Wire Rope

Wire Rope