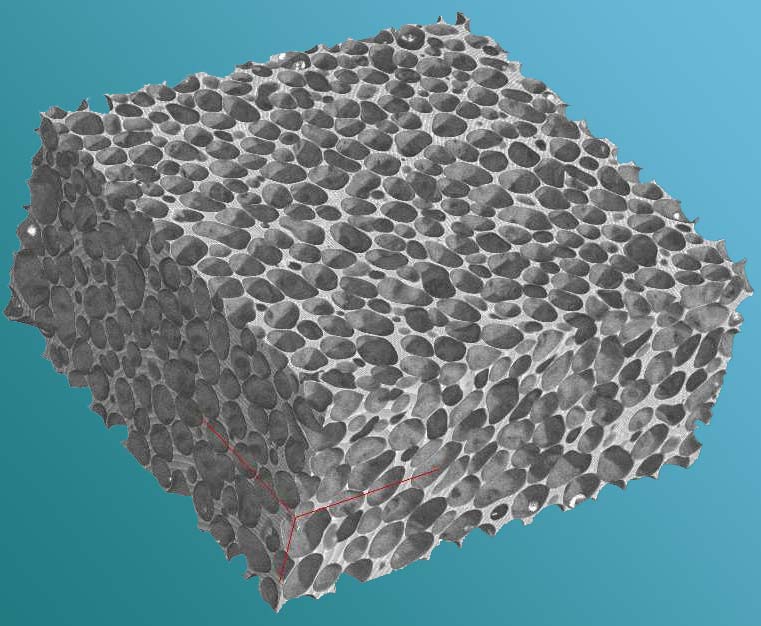

A metal foam is a cellular structure consisting of a solid metal, frequently aluminium, containing a large volume fraction of gas-filled pores. The pores can be sealed (closed-cell foam), or they can form an interconnected network (open-cell foam). The defining characteristic of metal foams is a very high porosity: typically 75-95% of the volume consists of void spaces. The strength of foamed metal possesses a power law relationship to its density, a 20% dense material is more than twice as strong as a 10% dense material.

AlMgCu foam blown by an intrinsic gas source

AlMgCu foam blown by an intrinsic gas source

Metal foam is what you get when you add a foaming agent, powdered titanium hydride, to molten aluminum, then let it cool. The result is a very strong substance that is relatively light, with 75-95% empty space. Because of its favorable strength-to-weight ratio, metal foams have been proposed as a construction material for space colonies.

Metallic foams typically retain some physical properties of their base material. Foam made from non-flammable metal will remain non-flammable and the foam is generally recyclable back to its base material. Coefficient of thermal expansion will also remain similar while thermal conductivity will likely be reduced.

You might also like

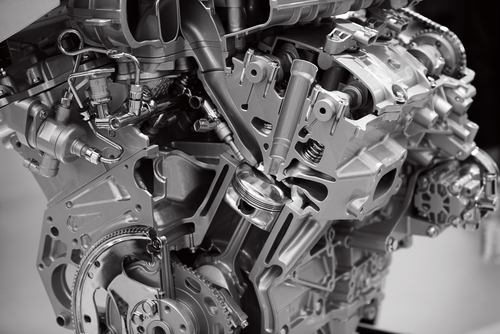

| Foundry and Casting A foundry is a factory that produces... | Superalloys A superalloy, or high-performance alloy,... | Aluminum “Hardening” - How it works? The term “heat treating” for aluminum... | Copper Alloys Copper is one of the most useful... |

Alloy Suppliers

Alloy Suppliers

Aluminum

Aluminum

Aluminum Extrusions

Aluminum Extrusions

Copper-Brass-Bronze

Copper-Brass-Bronze

Nickel

Nickel

Magnets

Magnets

Stainless Steel

Stainless Steel

Stainless Steel Tubing

Stainless Steel Tubing

Steel Service Centers

Steel Service Centers

Titanium

Titanium

Tungsten

Tungsten

Wire Rope

Wire Rope