Sheet Metal - Overview

Sheet metal is simply metal formed into thin and flat pieces. In 1887, Robert Kellerstrass, secretary of the Tin and Cornice Makers Association of Peoria, Illinois—a local sheet metal workers’ union—began agitating for the formation of a national sheet metal workers’ union. The union was founded on January 25, 1888 in Toledo, Ohio, as the Tin, Sheet Iron and Cornice Workers’ International Association. A second Canadian local formed in Montreal in 1900, and a Vancouver local in 1902.

Sheet metal is simply metal formed into thin and flat pieces

Sheet metal is simply metal formed into thin and flat pieces

The union joined the American Federation of Labor (AFL) in 1889. The Panic of 1893 weakened the union significantly, however, and the union’s finances collapsed. The AFL revoked the Tin, Sheet Iron and Cornice Workers’ charter in 1896, even though many locals continued to exist.

The union reorganized in 1897 as the Amalgamated Sheet Metal Workers’ International Association, and was rechartered by the AFL in 1899. In 1902, the Amalgamated Sheet Metal Workers’ union instituted its first national death benefit for its members.

In 1903, the Amalgamated Sheet Metal Workers’ merged with the Sheet Metal Workers National Alliance, a secessionist group that had broken away from the union in 1902, creating the Amalgamated Sheet Metal Workers’ International Alliance. In 1907, the union merged with the Coppersmiths’ International Union.

Application Sheet Metal

Application Sheet Metal

The union became embroiled in a bruising battle with the plumbers’ and carpenters’ unions in 1919. Railroad shop workers from the machinists, blacksmiths and plumbers met in St. Louis, Missouri in 1920 after a number of local plumbers’ railroad unions defected to the Amalgamated Sheet Metal Workers.

In 1921, the federated union disbanded, but the Amalgamated Sheet Metal Workers won substantial jurisdictional concessions from the plumbers. The conflict would continue into the 1950s, substantially weakening the Amalgamated Sheet Metal Workers. Finally, on April 26, 1955, the National Mediation Board reaffirmed Amalgamated Sheet Metal Worker jurisdiction over plumbing and pipefitting work in the railroad industry.

The introduction of metal moldings in buildings also created a problem for the union. By a 3-to-1 majority, delegates to the Building Trades convention voted in favor of the Amalgamated Sheet Metal Workers. The carpenters, then the second-largest union in the AFL, withdrew from the Building Trades and initiated a series of jurisdictional strikes against the Amalgamated Sheet Metal Workers at job sites nationwide. The BTD retaliated by asking AFL president Samuel Gompers to revoke the carpenter’s union charter.

The carpenters’ union disaffiliated again. The carpenters’ union continued to conduct strikes against the Amalgamated Sheet Metal Workers, and increasingly won the support of building contractors and local building trades councils. The National Board of Jurisdictional Awards also voted in favor of the Amalgamated Sheet Metal Workers. But the pressure by the much larger carpenters’ union proved too great, and the Amalgamated Sheet Metal Workers conceded jurisdiction over interior work in 1926.

Sheet Metal Art

Sheet Metal Art

The Amalgamated Sheet Metal Workers’ railroad affiliates were deeply involved in the Great Railroad Strike of 1922, which proved to be a disaster for the union’s railway unions.The Amalgamated Sheet Metal Workers’ absorbed the chandelier, brass, and metal workers in 1924, and once more changed its name—this time to the Sheet Metal Workers’ International Association. In 1926, the Sheet Metal Workers co-founded the Railway Labor Executives Association, a union lobbying group.

During World War II, Sheet Metal Workers members assisted in the building of buildings, experimental machinery, and atomic weapons-making equipment at Oak Ridge, Tennessee, as part of theManhattan Project. In 1946, the Sheet Metal Workers became one of the founding members of the Atomic Trades and Labor Council.

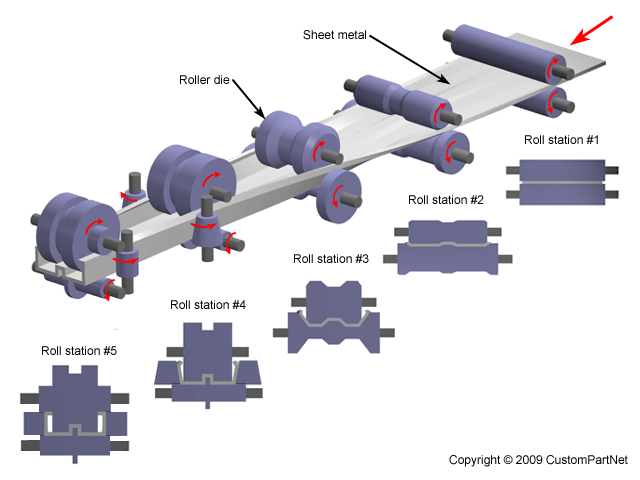

The Sheet Metal Workers are notable for negotiating a number of “firsts” in the construction industry. In 1950, Local 28 negotiated the first pension plan in the construction industry. In 1960, the Sheet Metal Workers organized its first political action committee, the Political Action League (PAL). Sheet metal is available in flat pieces or as a coiled strip. The coils are formed by running a continuous sheet of metal through a roll slitter.

The thickness of the sheet metal is called its gauge. The gauge of sheet metal ranges from 30 gauge to about 8 gauge. There are many different metals that can be made into sheet metal, such as aluminum, brass, copper, steel, tin, nickel and titanium. For decorative uses, important sheet metals include silver, gold, and platinum (platinum sheet metal is also utilized as a catalyst.)

Sheet metal has applications in car bodies, airplane wings, medical tables, roofs for buildings and many other things. The three most common stainless steel grades available in sheet metal are 304, 316, and 410.

Grade 304 is the most common of the three grades. Grade 316 offers more corrosion resistance and strength at elevated temperatures than 304. The four most common aluminium grades available as sheet metal are 1100-H14, 3003-H14, 5052-H32, and 6061-T6. It maintains high corrosion resistance and weldability. Grade 6061-T6 is a common heat-treated structural aluminium alloy.

You might also like

| Metal Forming Processes Forming Processes of Metal Metal deformations... | Deep Drawing What is Deep Drawing ? Deep drawing manufacturing... | Laser Cutting - Overview What is Laser Cutting ? Laser cutting is... | Galvanized Steel - a Definition What is Galvanized Steel ? Sheet, strip,... |

Alloy Suppliers

Alloy Suppliers

Aluminum

Aluminum

Aluminum Extrusions

Aluminum Extrusions

Copper-Brass-Bronze

Copper-Brass-Bronze

Nickel

Nickel

Magnets

Magnets

Stainless Steel

Stainless Steel

Stainless Steel Tubing

Stainless Steel Tubing

Steel Service Centers

Steel Service Centers

Titanium

Titanium

Tungsten

Tungsten

Wire Rope

Wire Rope